Regenerative gas production

In biogas plants, biological wastes and other decomposable biomass feedstocks are decomposed by bacteria in the absence of oxygen. The target product is biogas consisting of about equal shares of methane and carbon dioxide. Apart from the direct local conversion of the biogas produced into electricity and heat, the gas is increasingly fed into the natural gas network.

State of the art

Production and injection of biogas into the public gas supply system represents a viable alternative for using wet biomass for energy production. For this purpose, the gas has to be processed and compressed to the pressure of the gas supply network. The fermentation methods presently used for the production of biogas are hardly optimized for biogas injection into the natural gas network. Considerable progress might be achieved by biochemical gas production at a pressure exceeding the atmospheric pressure used so far.

Technology

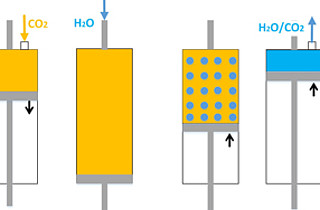

In cooperation with the University of Hohenheim, KIT scientists of the DVGW (German Technical and Scientific Association for Gas and Water) test laboratory at the Engler-Bunte Institute developed an innovative fermentation concept to optimize the production and injection of processed biogas into the gas network. The new process is developed under a joint research project and aimed at enhancing the efficiency of biogas production and processing. The new process consists of two stages. The biomass is converted micobiologically into gas in two reactors, with the second stage being operated at increased pressure. As a result of this two-stage pressurized fermentation, compression of the biogas is no longer required.

Advantages

Consequently, energy consumption is reduced by about 25 to 30% and no operation costs arise for processing to a biogas suited for injection into the gas network. Another advantage consists in the fact that gas cleaning is facilitated, as the gas is produced under pressure and, hence, of better quality. As a result of the increased pressure, the biogas contains a very large methane fraction of up to 90%. This faciliates downstream gas processing.

Options for companies

KIT is looking for partners interested in setting up a pilot plant.

Your contact person for this offer

Innovation Manager Energy Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25335

Email: pelisson-schecker@kit.edu