Efficient pressure water scrubbing

In Germany, the use of gases from natural sources and renewable energies such as biogas has increased in recent years. Before they are further processed or fed into the public gas grid, the gas mixtures need to be pre-processed. With the aid of technical solutions, they are separated into their raw gas components, such as methane, carbon dioxide or hydrogen sulphide, in order to use them in various branches of industry, such as the food industry, waste water treatment or energy generation.

State of the art

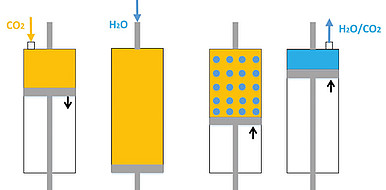

One common biogas purification method is pressure water scrubbing, which is based on the physical effect of dissolving gases in liquids. Here, in an isentrope, two-phase process, the gas to be separated is first compressed under pressure, as the solubility of the gas increases with increasing pressure. The compressed gas is then injected into a washing solution, a liquid absorbing agent. Here the gas is absorbed by the liquid.

Technology

Scientists of the Engler-Bunte-Institute (EBI) at KIT have developed an energy-efficient method that significantly reduces the compression effort required for pressure water scrubbing. The single-phase method centers on the simultaneous progression of compression and absorption. To densify the gas, it is fed into a reciprocating compressor fitted with a atomizer. During compression, the washing solution – in this case water – is injected into the gas to be absorbed in the form of droplets. Atomization accelerates material transport through an increased exchange surface. With their large heat capacity, the droplets act as an energy store for sensible heat.

Advantages

In comparison to conventional, two-phase pressure water scrubbing, the compression effort can be reduced by around 40 % with the new method: on the one hand through the permanent reduction of the volume of gas to be compressed or absorbed, and on the other through almost isothermal compression.

Options for companies

The method can be applied to all water-soluble gases and was tested in an experimental plant at the Institute. KIT is seeking partners for joint development projects and for industrial application.

Images close open

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu