Methane from biomass

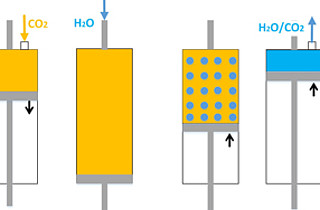

Germany's opt-out of nuclear energy leads to an increasing interest in energy production from renewable resources. Apart from solar and wind energy as well as geothermal processes, attention of politics and utilities focuses on the use of biomass for energy production. Lignin-containing (wooden) biomass can be converted into synthesis gas by gasification. This synthesis gas consists mainly of carbon monoxide and hydrogen. By means of the methanation reaction, synthesis gas can be converted into a methane-rich gas (substitute natural gas-SNG) which can be fed into the existing natural gas network. To efficiently operate decentralized methanation plants based on biomass feedstocks, process-related challenges have to be mastered. Above all, temperature management is needed, as SNG synthesis or methanation has to be performed in a closely limited temperature range. This requires efficient removal and use of the heat of the highly exothermal reaction. The new process for methanation developed by the Engler-Bunte Institute is based on ionic fluids in a bubble column reactor that is suited in particular for smaller and decentralized biomass facilities. The synthesis gas produced by biomass gasification is fed into the three-phase reactor and methanation takes place on the surface of very small catalyst solids (particle diameter about 50 - 100 µm). The ionic fluids used as the liquid reactor phase have two functions. Firstly, they serve as a medium for dispersion of the catalyst particles. Secondly, they ensure optimum removal of the heat produced by the methanation reaction. The relatively young group of ionic fluids is particularly suited for use in SNG synthesis due to their high thermal capacity, high solubilities for the educt gas, and low vapor pressure. In the closed circuit of the reactor with cooling, these rather expensive ionic fluids are a non-recurrent investment, as they do not evaporate. In the optimum case, the product gas is not contaminated. The process is highly attractive for small and medium plant sizes in the two-digit megawatt range used for energy production from decentrally arising biomass.

Your contact person for this offer

Innovation Manager Energy Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25335

Email: pelisson-schecker@kit.edu