Published on April 07, 2022

The positive turn for carbon dioxide: How greenhouse gas becomes a raw material

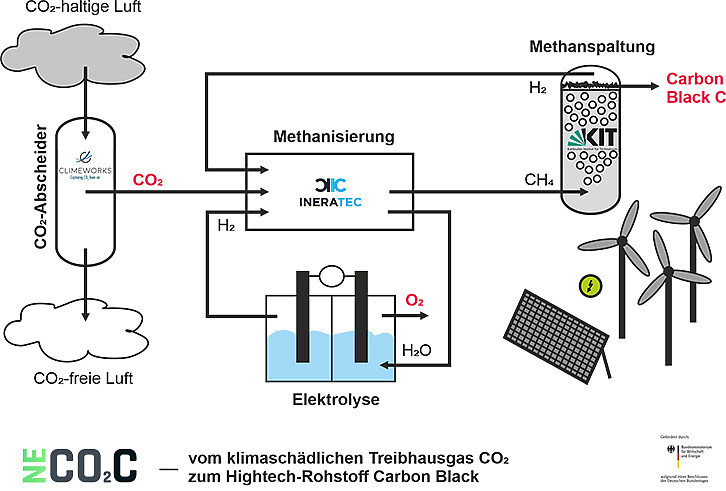

In the debate about climate change and the causes of global warming, emissions from the combustion of fossil fuels, such as in power plants or industrial production processes, are at the top of the list of polluters. Carbon dioxide (CO2) constitutes the lion's share of the so-called greenhouse effect. In order to slow down the associated climate changes and avert the resulting climate crisis, science and industry are already pulling out several stops: on the one hand, the avoidance and reduction of emissions, and on the other hand, the storage of carbon dioxide in the ground. At KIT, a globally unique approach is developed in the research project NECOC (NEgative CarbOn dioxide to Carbon): Extracting excess CO2 from the air and converting it into the raw material carbon black, also called industrial soot.

Closing the CO2 cycle

Since 2019, the project consortium consisting of KIT and the industrial partners Climeworks Deutschland GmbH and INERATEC GmbH has been working on the pioneering process. Dr. Benjamin Dietrich from the Institute of Thermal Process Engineering (TVT), who is coordinating the project for KIT, explains, "The aim of the project is to set up a pilot plant at Campus North that demonstrates the complete process of removing CO2 from the earth's atmosphere all the way to converting it into carbon black." The highlight here is that the CO2 is permanently removed from the atmosphere. As a result, the process realizes negative greenhouse gas emissions. "Our shared vision is to convert climate-damaging CO2 into a meaningful and economical use," Dietrich continued.

The key to the aim is the combination of all three core technologies of the cooperative partners: CO2 capture, methanation and methane splitting. Adrian Stetter, project manager in the plant engineering division at Climeworks, emphasizes, "The interconnected operation alone is a huge novelty. The challenge in the project was to couple the established processes and plants of all partners in one process chain and form a new closed system."

The prerequisite: carbon dioxide from the atmosphere

With its "Direct Air Capture" (DAC) technology, Climeworks GmbH creates the basis for supplying the process chain in NECOC with the necessary CO2. Stetter explains how direct air capture of CO2 works: "In a two-stage process, carbon dioxide is first adsorbed from the air. In this process, the ambient air is sucked through a CO2-selective filter material, similar to a vacuum cleaner. In the second step, the filter material is heated, releasing the carbon dioxide again in high quality." So far, the Swiss company's core business is to capture carbon dioxide from the air and feed it into the ground (Direct Air Capture & Storage) or make it available for further use (Direct Air Capture & Utilization) in other applications, such as carbonated beverages. "Pioneering projects like NECOC show us that reuse is becoming increasingly important. With the direct transformation of CO2 from the air into a value product, we are reaching a whole new level. We are thus making a decisive contribution to combating climate change," emphasizes Stetter.

The transformation: climate-friendly methanation

Climeworks and INERATEC have already collaborated on research projects in the past. This is because carbon dioxide is required as a starting material for the synthetic production of fuels, in which INERATEC specializes. Combined with hydrogen, INERATEC's modular chemical plants for power-to-X and gas-to-liquid processes are used to synthetically produce climate-neutral fuels (e-fuels) and sustainable basic chemicals such as wax. The company located in Karlsruhe, which emerged as a spin-off from KIT, contributes its methanation reactors (power-to-gas) to the NECOC project.

Dr. Tim Böltken, Managing Director of INERATEC, makes it clear: "Climate change cannot be tackled by a transport transition alone. There are other industries that rely on products that cannot be electrified or replaced. We see a lot of potential in NECOC: the methane we produce with our technology is turned into a high-quality end product through the subsequent methane pyrolysis. This could allow us to replace fossil raw materials and provide input materials for industry."

Methanation at INERATEC's plant is an important process step in the separation of atmospheric carbon dioxide. "The purified CO2 from the air capture DAC is mixed with hydrogen in the methanation reactor. For this, part of the hydrogen comes from electrolysis and another part from methane splitting," describes chemical engineer Böltken. Under pressure and high temperatures, the two gases then react catalytically to form synthetic methane and water. The emerging waste heat can in turn be integrated into the heat-intensive CO2 capture process. In this way, synergies between all three process steps are optimally utilized.

Completion: Methane pyrolysis in liquid metal

The synthesis of methane is followed by the final step to high-purity carbon powder by means of methane pyrolysis. This process has been developed and scientifically examined at the Karlsruhe Liquid Metal Laboratory (KALLA) as a facility of the KIT Institute for Thermal Energy Technology and Safety (ITES) in recent years. The heart of the methane pyrolysis is a special liquid metal bubble column reactor. "The obtained methane gas is fed into the tempered reactor filled with liquid tin and forms rising gas bubbles. In the gas bubbles heated by the surrounding hot metal, decomposition of the methane into gaseous hydrogen and solid, elemental carbon takes place," explains process engineer Dietrich. The methane degrades, in a sense, into its constituents, which are removed in a downstream separation device. The microgranular carbon powder produced in this way, carbon black, can finally be economically utilized. The resulting hydrogen is fed back into the methanation process.

New black gold

Carbon black is a high-tech product that is used, for example, in the paint industry, in lightweight construction and in the polymer and electronics industries. The deep black industrial carbon black consists of almost 100 percent carbon and is currently produced industrially in high-temperature reactors with the aid of special combustion processes from fossil raw materials. Various qualities of carbon black can be produced in different aggregate sizes and structures. The NECOC process can also be used to produce carbon black particles with defined characteristics. By means of adjustable process parameters, the end product carbon black can be tailored to the specific application as required. Researcher Dietrich is looking forward to the future with confidence: "Our innovative process could completely replace the previous one. While conventional production requires the use of fossil sources, we remove the greenhouse gas CO2, which is considered harmful, from the air and convert it into a sustainable raw material. By producing carbon black from 100 percent of the carbon dioxide extracted from the air, we create negative emissions and at the same time a sustainable alternative to fossil raw materials for future generations."

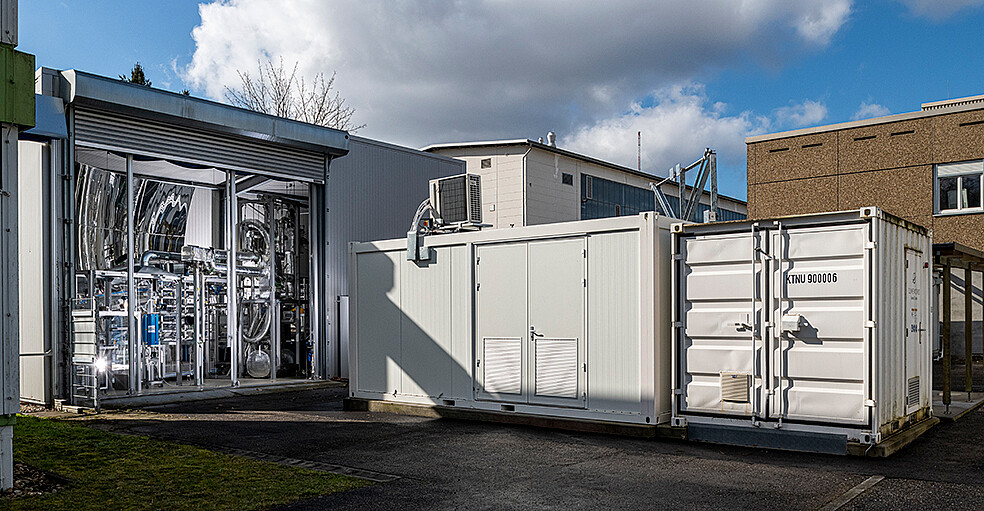

Pilot plant goes into operation

The individual process steps were designed by the project partners to be compatible with each other in terms of scale and development status, so that they can now be merged into a complete system according to plan. This year, the individual modules have reached their destination at Campus North of KIT and are currently being assembled into a demonstration plant. The project partners are optimistic: "In July 2022, the pilot plant should go into operation for the first time. It is clear to all involved that we will not yet be able to obtain carbon black with the plant on the scale that is demanded industrially. We first want to show that our approach works on more than just paper." The goal is to demonstrate operation over a longer period of time. Entrepreneur Böltken feels certain: "The NECOC process is a technological approach for a sustainable future in several respects. It combines a direct contribution to solving the climate problem with a building block of a post-fossil raw material supply. The sale proceeds of the carbon black could, in perspective, cover the entire process costs and thus realize the conversion into negative CO2 emissions at almost no cost."

NECOC at the Hannover Messe 2022

You can get more detailed information about the NECOC project at the Hannover Messe this year. Contact persons of the joint project will be available at the KIT booth in the Energy Solutions area. As a subscriber to the RESEARCH TO BUSINESS newsletter, you will receive a free e-ticket for your trade fair visit directly by e-mail.

Kontakt

comments about this article

No Comments