Published on December 17, 2021

Sustainable industrial products - How the change of direction in production succeeds

Sustainable production means to manufacture goods in a resource-saving way and to preserve the regenerative capacity of natural resources. The primary goal here is to secure the basis of life for future generations. Therefore, consumers increasingly demand products that are produced with low raw material and energy consumption. In the KIT Business Club, such developments also come directly. "Inquiries from member companies about sustainable technology developments from KIT increased strongly this year," explains Dr. Markus Bauer, head of the network. "Resilient raw material supply and efficient resource use play an increasingly important role for many industrial sectors," emphasizes Prof. Dr. Thomas Hirth, KIT Vice President for Innovation and International Affairs and spokesman of the THINKTANK Industrial Resource Strategies. At the KIT Business Club's "Sustainable Products and Sustainable Production" theme day on November 25, 2021, speakers and participants explored some of the challenges and new solutions.

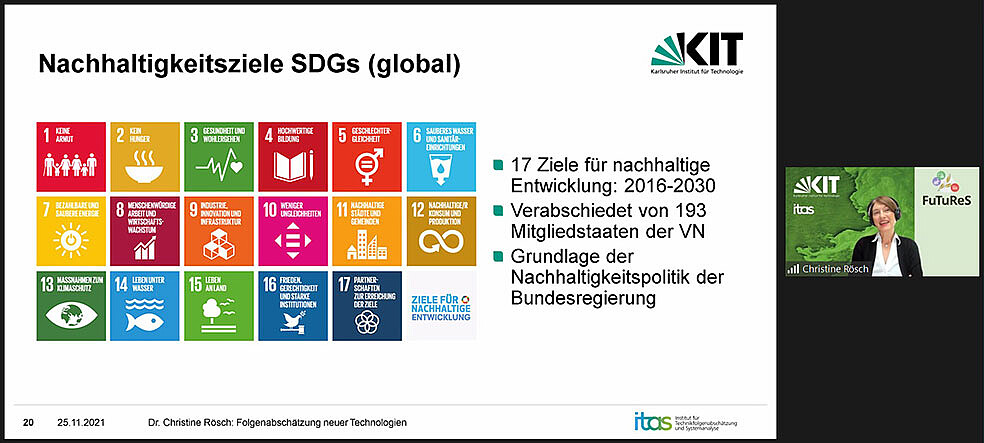

In view of many different fields and aspects, sustainability is difficult to grasp and evaluate. At the global level, the United Nations has therefore defined a comprehensive framework for action in recent years with the 17 'Sustainable Development Goals': "From the targets formulated there, a set of indicators can be derived for government and society to measure and evaluate progress in achieving the goals," as Dr. Christiane Rösch from the Institute for Technology Assessment and Systems Analysis (ITAS) explained in the first presentation. Analogously, strategies are also being developed at many companies that take up the criteria from different fields of action and promote the path to sustainable development.

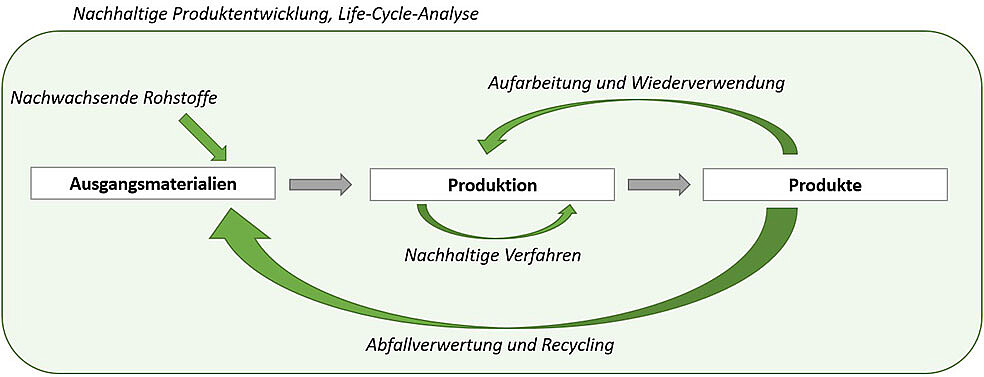

The theme day highlighted above all the areas of products and production as important fields of action for every company. Starting points for more sustainability can be found along the entire product creation chain, starting with the input materials, through the manufacturing processes, to the products themselves (Fig. 1).

Renewable raw materials, sustainable processes

- Materials from renewable sources reduce the carbon footprint of products, for example. In terms of performance, many of these materials can now compete with conventional materials and lead to more sustainable end products. Prof. Michael Meier of the Institute of Organic Chemistry (IOC) has developed manufacturing processes for a range of more sustainable plastics. He emphasizes: "It is important that the entire process with all waste products and energy flows is always taken into account when considering sustainability, and that the economic viability remains presentable.

Sustainable Product Development

- Product development and design are already important factors in achieving more sustainable products. Markus Spadinger from the Institute for Product Development (IPEK) explains: "For optimization, the socio-technical overall system, i.e. also the potential user and his interaction with a product, must always be included". The toolbox of product development methods for sustainable, future-proof solutions includes trend analyses, scenario techniques, or roadmapping for different product generations.

Waste utilization

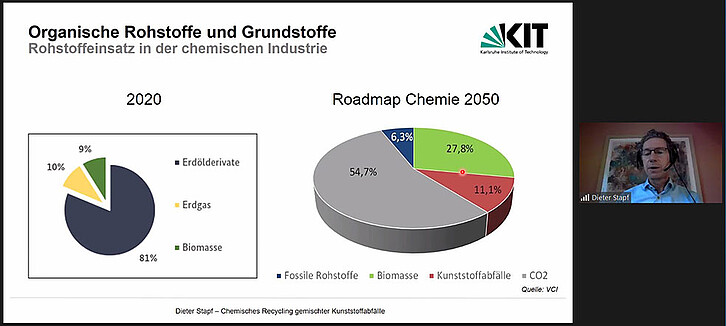

- To reduce waste streams and the production of petroleum-based feedstocks, recycling is essential. The main focus of the research of Prof. Dieter Stapf from the Institute of Technical Chemistry (ITC) is on complex material composites and material mixtures, the amount of which will increase strongly in the near future, e.g. from electronics or durable building products. Processes for recycling this group of waste materials are particularly challenging, but with chemical molecular recycling via pyrolysis, KIT is working on an effective way to recover basic chemical substances from these materials.

Remanufacturing and reuse

- Remanufacturing of entire products or components also offers great potential. Today, only a very small percentage of discarded end-of-life products are reused or recycled in this way - also due to a lack of customer interest. According to Felix Klenk of the wbk Institute for Production Technology, the reasons for this lie in particular in the lack of a reliable supply and logistics chain for end-of-life products, as well as in the lack of availability of information about the complete life cycle to date. The wbk is working on the development of such logistics and information systems, but also on solutions for dismantling, using the example of automotive components.

Life Cycle Analyses

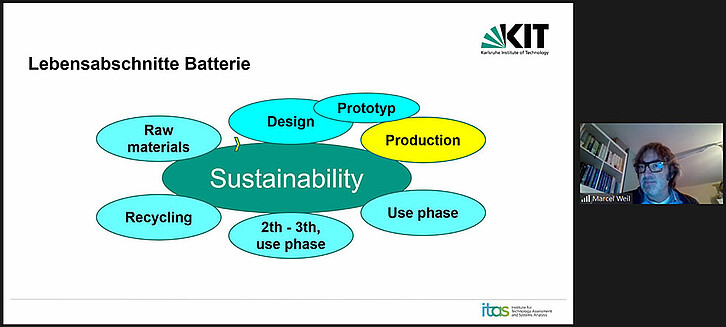

- Current developments in the field of battery systems for a wide range of applications are very dynamic. Therefore, a comprehensive sustainability analysis is all the more important. The life cycle analysis work of Dr. Marcel Weil from the Institute of Technology Assessment and Systems Analysis (ITAS) provides valuable insights into critical and non-critical raw materials, as well as into the sustainability of different cell designs and production routes. At the same time, they also show that a suitable usage scenario and recycling play a major role in the sustainability of a battery system.

After the intensive digital exchange, the guests of the theme day agreed: For more sustainable products and production systems, there are many things that can be done. But for the final evaluation, it is always essential to consider the entire system and the entire life cycle. Sustainability should never be considered in absolute terms, but always in comparison with other solutions.

The theme day addressed a number of these small and large levers. This resulted in a compact overview with many individual impulses on sustainability research at KIT, which the participants from industry can take back to their companies. The KIT Business Club would like to thank the speakers and guests!

comments about this article

No Comments