Published on May 21, 2020

Safe home storage for decentralized power supply

Sichere Heimspeicher für die zentrale Stromversorgung

In times of the energy transition, power is no longer generated and provided only by large energy companies or municipal utilities. The technical possibilities of photovoltaics create the fundament that now everyone can produce their own renewable energy with solar cells. A well-planned solar system on the roof can ensure the supply of electrical energy for an entire family. In 2019 a total of nearly 60,000 new small photovoltaic systems in the segment < 10 kilowatt peak (kWp) were notified to the Federal Network Agency. Stationary home storage systems are indispensable to be able to use green electricity for own consumption efficiently and economically. These home power storage facilities guarantee the intermediate storage of the energy generated until it is consumed in the home, thus balancing out the fluctuation of solar energy.

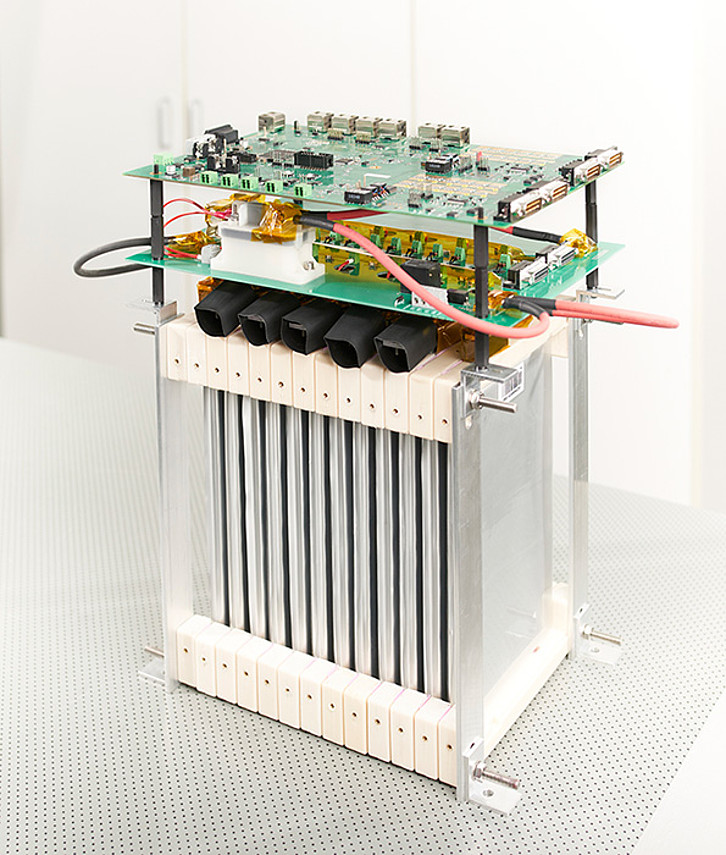

RCT Power GmbH based in Constance has specialised in photovoltaic power storage systems for own consumption and offers modular home storage systems with a storage capacity between three and twelve kilowatt hours for new systems and as a retrofit option. The special characteristic: The Battery Management System (BMS) installed in the RCT home storages was developed in close cooperation of RCT Power GmbH with the Institute for Process Data Processing and Electronics (IPE) of KIT. Dr.-Ing. Thomas Blank, head of the Electronic Packaging Laboratory at IPE, explains: "A research focus at IPE is on battery-driven, power electronic systems as well as technologies for their manufacture and assembly. This includes the development, optimization and characterization of power electronic modules as well as their integration into battery electric, stationary and mobile systems. We regularly contribute our expertise to research and industrial cooperation.”

Technology match

The industry-related research at IPE attracted the attention of RCT Power almost five years ago. Thomas Hauser, the Managing Director of the company, remembers: "We wanted to expand our core business of solar inverters and were looking for a development partner to build a modular power storage system using high-performance lithium-ion batteries. For this purpose, we needed a battery management system that was individually adapted to this. After several attempts with companies we came across the portfolio of the IPE." From the initial contact, concrete plans for cooperation developed very quickly, so that a KIT-funded technology transfer project for joint product development could start in 2016.

The aim of the three-year project was to adapt an already functional battery management system of the IPE in such a way that it can be economically used and operated in stationary home storage systems for high voltage levels." For many years, we have been developing highly specialized BMS for large lithium-ion storage systems that are used in mobile applications such as cars and buses. We used our years of experience to realize a customized BMS for RCT Power's stationary power storage systems in a very short time," says group leader Blank. After just one year of project runtime, the first co-developed home storage units with the battery management system went on the market to validate the power storage systems close to the customer. The use under real conditions showed already during the early development phase what private customers focus on.

Storing solar energy safely

"When the sun shines, a photovoltaic plant usually produces more energy than an average household consumes during the day. Without a power storage unit, these surpluses from the solar system are fed into the municipal grid and are lost for personal consumption," describes home storage expert Hauser the situation. In a stationary power storage, several batteries are linked together to provide the highest possible storage capacity for the intermediate storage of green power. The lithium iron phosphate batteries used are considered efficient and reliable energy storage devices. During operation, however, they have to be protected against overcharging, deep discharge, over-current, over-temperature or excessively low temperatures. Therefore, special safety requirements are demanded of the entire battery system. One of the essential tasks of a BMS is to operate the battery cells in a safe operating range at all times. For this purpose, it monitors all safety-critical parameters.

Batteries under control

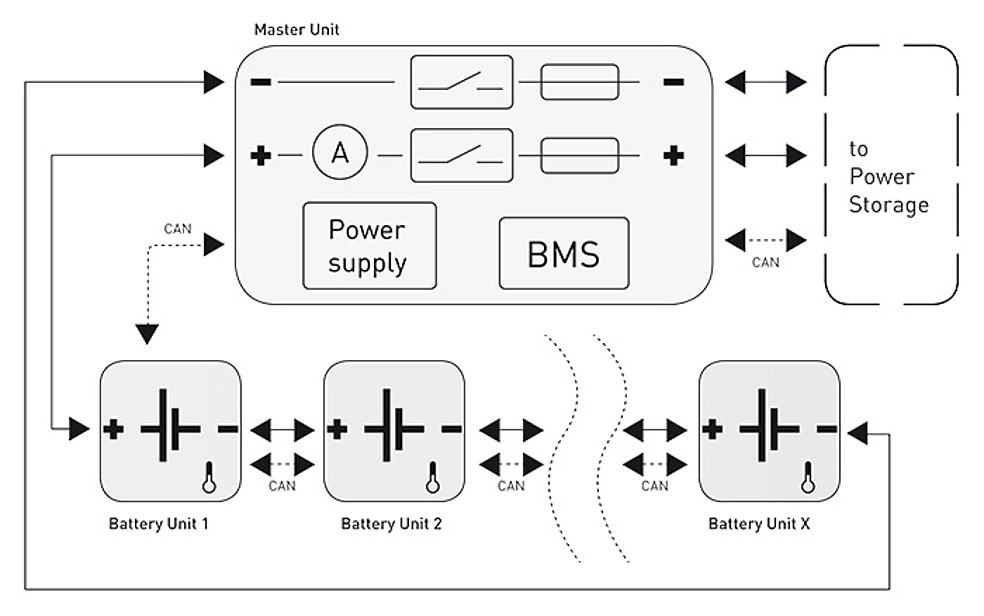

Simon Bischof, who was involved in the project at IPE, emphasizes: "The battery management system is an independent control unit that ensures the monitoring and safety of a battery system. Without working control mechanisms, there is a risk of system failure due to a short circuit or overheating. The BMS is therefore an essential key component for reducing the system-inherent sources of danger and for operating a safe battery home storage system". A BMS accomplishes important tasks for adherence to battery safety: measuring and monitoring the individual cell voltages and temperatures, controlling the protective devices, such as relays, as well as communication with other systems, e.g. converters and controls. In addition, the control component ensures the necessary cell balancing. In addition, data such as the depth of discharge and the number of charge cycles of the individual battery cells are filed and can be called up as needed.

High standards for even more safety

In such a sensitive battery system, the battery management system itself must not pose a danger under any operating conditions and must therefore be intrinsically safe. The system developed at IPE is especially designed for safety-critical applications and has safety functions that go far beyond the current state of the art in the home storage market. Project manager Blank points out: "Our BMS satisfies much more strict requirements, such as those required in the field of e-mobility. As the normative requirements for home storage systems are expected to become significantly stricter in the coming years, we are already fulfilling key aspects of upcoming requirements for Li-ion battery systems today. This is because the pre-developed BMS of 2015 was originally developed for the automotive industry, and the scientists have retained the high safety standard - entirely in the interests of prospective home storage users.

From the base frame to the product

Although the development cooperation between KIT and RCT Power was based on an existing technology, several milestones still had to be reached before market entry. Intensive preliminary talks and several iterations during the project period were necessary to define the specifications for the future battery system in the necessary detail and to adapt them to changing scope conditions. The team at IPE was entrusted with the circuit and layout development for the BMS and the electrical measurement technology. Electrical engineer Bischof gives an overview of the development stages: "An important initial step for the design of the new home storage system was the characterization of lithium iron phosphate cells from different manufacturers with the aim of selecting a reliable and cost-effective cell for the storage. Further, in the first phase of the project, a new sensor system for capturing the battery voltage and current was developed, which was based on an existing sensor system of the IPE".

However, the battery management as an embedded system in the solar inverter could not be considered as a stand-alone system, but rather was closely related to the inverter technology of RCT Power, which was further developed in parallel by the in-house development engineers. Data are exchanged between both systems and energy flows are regulated. "In order to enable the hardware components to work with each other appropriately, a complex control system had to be coded and documented for communication between the BMS and the inverter," says Blank and adds: "Overall, the teamwork in the project was extremely focused and intensive. We were regularly on site at RCT and vice versa. The close communication finally resulted in a product that has achieved very high customer acceptance within a very short time". The construction of the complete system consisting of inverter, batteries and BMS - under economical and constructive aspects - was eventually one of the challenges for RCT Power.

Awarded home storage

In 2019, the technology transfer project came to an official end and the market launch was already successful. The good sales figures of the home storage speak for themselves, and independent expert reports, such as the "Stromspeicher-Inspektion" 2020 - conducted by the Berlin University of Applied Sciences - attest to the highest efficiency and quality of the RCT products with embedded BMS over the last three years. The RCT Power System for new installations once again ranked first as the best system under eight kilowatt hours. In competition with all the systems tested, some of which had larger storage tanks, it was once again among the "top three". The managing director Thomas Hauser stressed: "Electricity storage systems should be effective and safe. That's why we have relied on state-of-the-art technology from the beginning. The battery management system of KIT was the fundamental cornerstone for the entire product range we offer our customers today".

comments about this article

No comments