Published on September 29, 2021

Project planning with added value

»Opening delayed by 10 months. Construction project costs nearly tripled. The construction industry is running out of materials.« – Reports like these are regularly in the press and whip up feelings. All indicators that the planning and coordination of major construction projects is a mammoth task. Construction planners and project managers are faced with the challenge of planning highly complex, extensive and multi-faceted sub-projects and trades under technical and safety-relevant, economic and legal as well as resource-saving aspects. With such large and complex projects, this is only possible with the help of IT tools for project management, such as Microsoft Project or Oracle Primavera. Despite the software support, the project success mostly depends on the experience of the planners. KIT and RODIAS GmbH have jointly developed a user-friendly software add-on that supports planners in time and cost optimization on a model basis.

Deconstruction as model project

"Project and resource management in the built environment have been the subject of research at the Institute for Industrial Production (IIP) since the 1990s," explains Dr. Rebekka Volk, who heads an eight-member research group in this area. The starting point for the research were deconstruction projects of all kinds: from conventional, urban and industrial buildings to nuclear power plants. The complexity of dismantling nuclear power plants can hardly be surpassed. Special requirements for safety, radiation protection, logistics and material flows as well as numerous approval processes mean that very detailed project planning is indispensable. "Because of the increasing requirements and complexity, our goal was to enable method-based optimization and analysis as well as to offer decision support in project and resource management," Volk continues. While initially only circular economy with material life cycles and recycling was the focus of research at the IIP, the range of topics has expanded in recent years to mathematical models and methods for project management.

Since 2014, Volks' research group has therefore been working on an algorithm for optimizing the planning of nuclear dismantling projects as part of cooperative third-party funded projects with industry participation, funded by the BMBF:

- MogaMaR – Model development of a holistic project management system for nuclear dismantling projects

- NukPlaRStoR – Development of a user-friendly cost-optimizing planning tool for nuclear dismantling projects taking into account material flows for resource planning

Convinced by the results of the MogaMaR project, RODIAS GmbH – an IT provider in the field of enterprise asset management and plant maintenance – joined the follow-up project NukPlaRStoR together with VPC Nukleare Dienstleistungen GmbH. The joint research results were so persuasive that RODIAS has been offering the models and methods for optimizing project planning developed at the IIP as the software product OPTIRA since mid-2020.

Add-on for planning tools

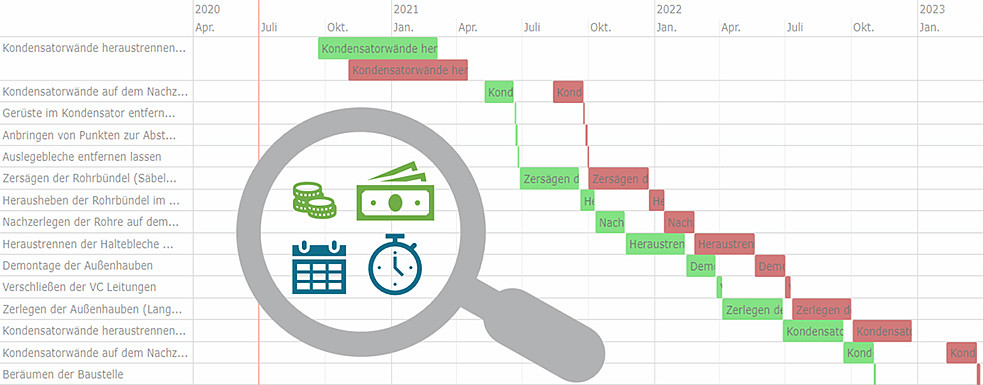

Peter Stängle from RODIAS explains: "Existing planning software does not always cover the multidimensional requirements of very complex projects. Here, the operational plans are based on the experience and knowledge of the planner, who visualizes the plans with the help of established software tools. With OPTIRA, we provide them an additional tool that evaluates planning scenarios in a data-based and automated manner and makes recommendations for action." OPTIRA is an add-on for conventional project planning software that optimizes complex projects in terms of time and overall costs. The algorithms developed at the IIP are integrated as an independent program library and take over the mathematical optimization. The IT experts at RODIAS have developed the software environment and necessary interfaces that enable intuitive handling of the models, data processing and visualization.

The add-on does not interfere with the established processes of the planners: A user plans as usual with his favorite tool, but then has the possibility to transfer via an interface the project planning completely to OPTIRA for optimization. Here the mathematical algorithm takes over the optimization on the basis of the individual project data. The planner can compare the optimization results with the original planning and decide on a scenario which is then returned to the planning software. Thus, it is conveniently possible to calculate an optimal project operational plan for each project phase as often as desired and to improve it in terms of planning.

With algorithms to the optimum

"Even in project plans with a few hundred activities and some dozens of different resources, such as personal or machines, it is almost impossible to manually implement the necessary planning adjustments in the course of the project duration and still guarantee an optimal resource utilization or cost calculation," emphasizes software expert Stängle. Here OPTIRA offers fully automated support for planners and project managers. The implemented algorithms can simulate countless planning alternatives and show the mathematically optimal project operational plan. Depending on the needs, a project can be analyzed in terms of project duration or total costs. The variants determined create a basis for decision-making and also make it easier to react quickly to changing boundary conditions in project planning. Volk, a business economist, points out: "With our method, optimized project operational plans for different scenarios can be calculated and visually displayed in the shortest possible time. This reduces planning uncertainties and allows planners to react more flexibly and adjust plans or resource allocations." The optimization is not only interesting for new planning, but already created project planning can also be verified.

In the NukPlaRStoR project, the cooperation partners RODIAS and VPC Nukleare Dienstleistungen have tested and proven the improvement potential of the software solution with practical data. This potential can be applied to projects of any kind: Potential users of the planning tool are (sub-)project planners in all industry sectors, such as power plant operators, construction or dismantling companies, project planners of wind farms, planning offices or consulting companies. Especially projects with high complexity and control density, such as the construction of large industrial plants, the establishment or dismantling of oil rigs, as well as infrastructure or grid expansion projects can benefit from the system-based optimization with OPTIRA. KIT and RODIAS are still working on additional functionalities in the project consortium until 2022, especially in the context of material flow planning and the optimization of logistics within the projects.

Contact

comments about this article

No comments