Smart factories for the world of tomorrow

Production is in the midst of a digital revolution. Technologies such as the Internet of Things (IoT), artificial intelligence and additive manufacturing with a wide variety of materials are enabling the development of 'smart factories' that can produce flexibly, efficiently and in a resource-saving manner. These new production methods offer companies the opportunity to increase their competitiveness while minimizing their ecological footprint. Modern production is driven by close cooperation between science and industry.

Investing in smart production technologies today lays the foundation for the industry of the future. Benefit from the extensive know-how at KIT: The development of new production techniques and tools, the construction of efficient plants and the planning of holistic production systems - also from the point of view of the circular economy - are among the research topics at KIT.

A selection from the production area

Technology offers of the KIT

- Plant engineering

- Automation / IT

- Filter technology

- Polymer industry

- Food industry

- Optical Industry

- Pharmaceutical industry

- Raw material and textile industry

- Process and production engineering

- Electrical engineering

Sensor-based sorting without compressed air

With a new optical sorter based on an area-scan camera and an array of mechanical actuators, bulk material can be separated without compressed air with high throughput and precision.

- Simulation and data processing

- Automation / IT

- Process and production engineering

- Mechanical engineering

- Measurement technology

- Safety technology

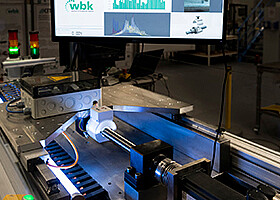

Intelligent condition monitoring in production

A camera system with a learning model enables fully automated image evaluation of wear condition or product features with artificial intelligence.

- Plant engineering

- Automotive industry

- Printing industry

- Polymer industry

- Process and production engineering

- Aerospace industry

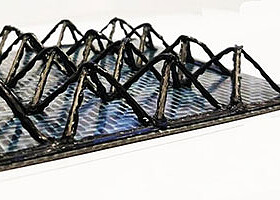

3D microwave printer for continuous fiber reinforced polymer

A new system for additive manufacturing by using microwave heating to print components made of continuous fiber reinforced composites quickly and efficiently.

- Coating technology

- Printing industry

- Electrical engineering

- Biotechnology

- Process and production engineering

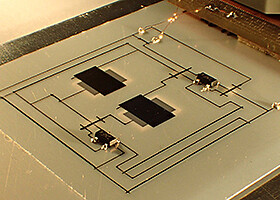

On-demand digital printing with aerosol jet print head

New aerosol-on-demand (AoD) printing process with a jet print head enables functional digital printing on uneven substrates even with small volumes of fluid.

Are you looking for a technical solution in the field of production technology or expertise on an individual issue in your company? We can help you find the right partners at KIT. Get in touch with us!

Do you know our other offers?

Gelungener Transfer – Produktion

Mobilizing semiconductor factories with AI

Digitalization and electrification lead to a global increase in demand for microchips. In order to make production in Germany more agile and competitive, KIT researchers are working on AI-based approaches for production planning in semiconductor manufacturing in the Autonomous Integrated Scheduling for Semiconductor Industry (AISSI) project together with Robert Bosch GmbH and other industrial partners.

MorePick and grip with QBIIK

Together with industrial partners, KIT researchers have developed the adaptive, autonomous QBIIK picking system. In future, with mobile logistics vehicles, industrial robots and tactile grippers, loads will be moved autonomously and supplies picked.

More

Light instead of solvent: UV hardening with LEDs

Together with mpg-lightsystems, scientists from the Lighting Technology Institute have developed a new generation of UV LED lights that makes paint hardening in the automotive sector with UV light more homogeneous and efficient.

MoreTradition meets high-tech in 3D freeforms

At the KIT ARBURG Innovation Center, scientists of the wbk Institute of Production Science are developing new technologies for the additive manufacturing of fibre-reinforced composite materials for individual small-batch series in collaboration with ARBURG GmbH + Co KG.