On-demand digital printing with aerosol jet print head

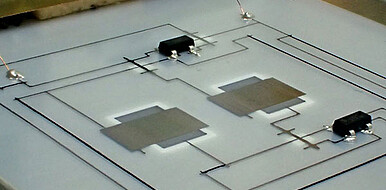

The printing of functional structures, such as conductors or capacitors, places new, higher demands on the printing process than the printing of classic print media. For example, the required quality of the structures in terms of physical and chemical properties is significantly higher.

State of the art

The piezo inkjet process is commonly used for functional Digital Printing: Ink drops are applied directly from a printing nozzle onto a flat substrate by Piezo excitation. Alternatively, the aerosol-jet process is used to print in other Viscosity ranges and for Topology steps of the substrate surface. In this case, Aerosol generation from a fluid takes place in a separate system with a relatively high minimum filling quantity. The aerosol is fed to a print head via a pipe system, which means that a fluid change requires complex cleaning and disposal of contaminated fluid residues.

Technology

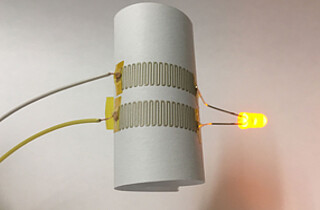

Scientists of the Institute for Automation and Applied Informatics (IAI) at KIT have developed a more flexible Jet print head for aerosols. The print head consists of a basic unit with a nozzle in which an easily exchangeable unit consisting of a fluid guide, a Piezo actuator, and an elastic element is inserted. For the Aerosol generation, a fluid is fed into the fluid guidance system, set in oscillation by the actuator and atomized directly at the nozzle opening. The aerosol is aerodynamically focused there by a sheath gas in such a way that a converging, accelerated aerosol flow is present after the nozzle outlet. During printing, the aerosol jet can be switched on and off quickly as required by means of piezo control without the need for an additional ink catcher (shutter).

Advantages

In the new print head, the fluid-carrying parts are designed as cost-effective disposable components, so that cleaning effort is minimized. Since Aerosol generation takes place directly in the nozzle, only small quantities of the fluid to be printed are required. A further special feature is that the print head can be freely oriented in space and can therefore be aligned as desired to the object to be printed.

Options for companies

In addition to printed electronics, the print head could offer added value in the biological field. Even with very small quantities of liquid samples, homogeneous structures for biological test series can be printed, while at the same time reducing material loss. The KIT is looking for partners for the technical implementation of the print head.

Images close open

Your contact person for this offer

Innovation Manager Mobility and Information Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25335

Email: julia.rast@kit.edu