Published on August 27, 2020

Light instead of solvent: UV hardening with LEDs

Strong colors, flawless surfaces and brilliant paintwork will delight every car owner. Damage to the paintwork is not only annoying, but also requires expert use and precision work when repainting. The goal of such a partial paint job is to restore the damaged areas in such a way that the repair is not visible to the naked eye. A common method of repair in specialized companies is painting with solvent-based paints. The drying effect here is based on the evaporation of the volatile solvents, while thermal energy in the form of warm air or infrared radiation acts on the paint layer. "Conventional paint hardening takes up to 2 hours. Disadvantageous is not only the temporal expenditure, but also the substantial risks for humans and environment due to the contained poisonous solvents", determines Michael Gumbert, managing director of mpg-lightsystems. According to the credo ‘from practice for practice’, master painter Gumbert and co-entrepreneur Peter Guterl are pursuing the vision of making UV curing practical and profitable as an environmentally friendly alternative for paint stores and vehicle workshops.

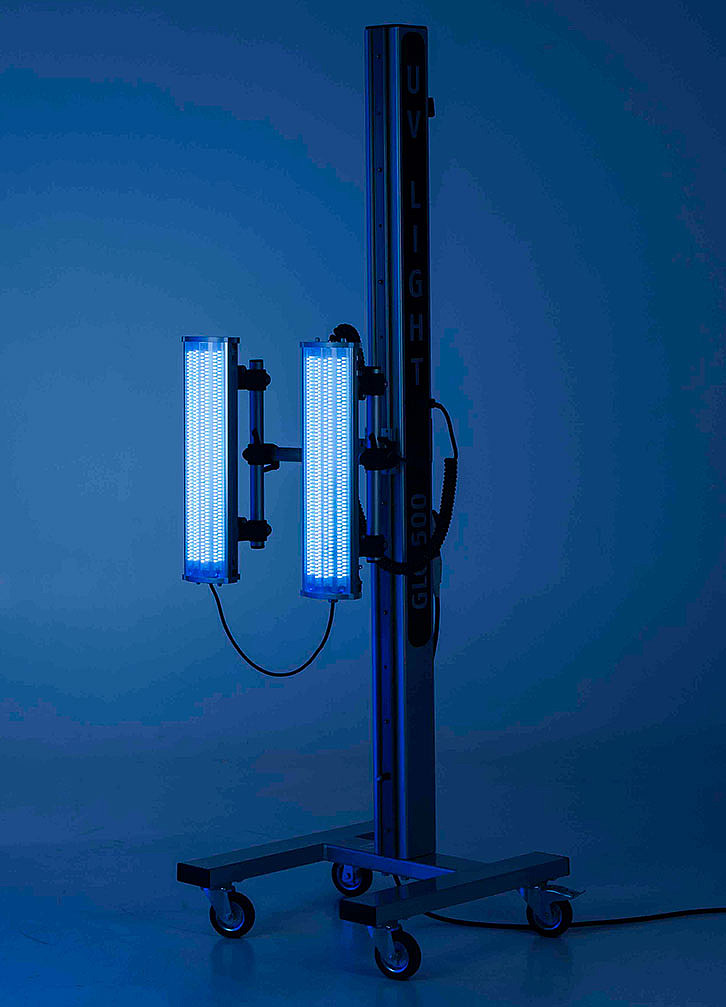

Using UV light, paint and filler can be cured without solvents. In this process, the liquid UV coating is stimulated to polymerize by a chemical reaction initiated by ultraviolet radiation and thus cured. mpg-lightsystems, based in Pirmasens, offers functional UV hardening equipment in two sizes for this purpose, which flexibly dries special UV hardeners and clear coats in the repair store. Product quality and safety were important to the entrepreneurs right from the start: "We had our products inspected by the KIT's Lighting Technology Institute according to the relevant standards and found that a circuit technology from the institute could further optimize our lights," Guterl remembers.

Dr. Michael Heidinger, who developed the patented circuit topology at KIT, explains: "During the certification measurements, we found out that the LED arrays used at that time emit the radiation unevenly. However, the homogeneous UV illumination is decisive for the quality of the repainting. The solution was obvious to the electrical engineer: "My approach of parallel circuitry makes it possible to achieve an even distribution of current and thus uniform illumination, which cures the UV coatings more homogeneously". Within the scope of a technology transfer project, the cooperation partners have jointly developed a new light circuit board to which the parallel circuit is applied. The LED board could be integrated into the proven, mobile mpg light holders.

"UV painting is a growing market and always new products are offered. By the hardening in seconds, connected with high energy saving potential and an environmentalcareful application UV painting systems are predestined for production processes with short cycle times , reports Gumbert. The lights of mpg offer a further advantage: By the use of long wave UV-A light no additional hardeners are needed and the health risk of UV radiation, such as sunburn, is again minimized for the painting specialists. "This combination makes the UV hardening to a high-quality and safe process", confirms the entrepreneur Guterl. Compared to infrared technology, the throughput can be increased by a factor of 12 with the mpg hardening equipment, whereby the energy consumption per hardening is reduced by a factor of 200.

The smaller hand lamp for small repairs is also suitable for 'Smart Repair', the comparatively inexpensive and quick repair of minor damage. Guterl thinks even further: "Modularization was important to us during the product development of the UV light. So we keep it open for us to equip various products up to industrial painting lines with the LED modules in the future". The scientist Heidinger is satisfied: "The circuit topology was originally developed for LED street lights. I am pleased that other areas of application can also benefit from it. mpg can now offer significantly higher quality lights that enable faster and more consistent paint hardening".

Further details on the circuit topology can be found in the technology offer: Economical lighting

comments about this article

No comments