Published on September 27, 2021

Platform MaterialDigital: Driver of digitalization in materials science

"What we are doing here with MaterialDigital platform is pioneering work in many ways. That means you have the chance to really get involved and develop and drive something completely new. It motivates us a lot in our day-to-day work, but at the same time it's a big challenge that we have to overcome. There is a lot that still needs to be done in the next few years in material digitalization. Nevertheless, we are proud of what we have already achieved with the platform", says Dr. Heike Fliegl, scientist at KIT's Institute of Nanotechnology (INT) and Managing Director of MaterialDigital, summing up her experience of the first project phase.

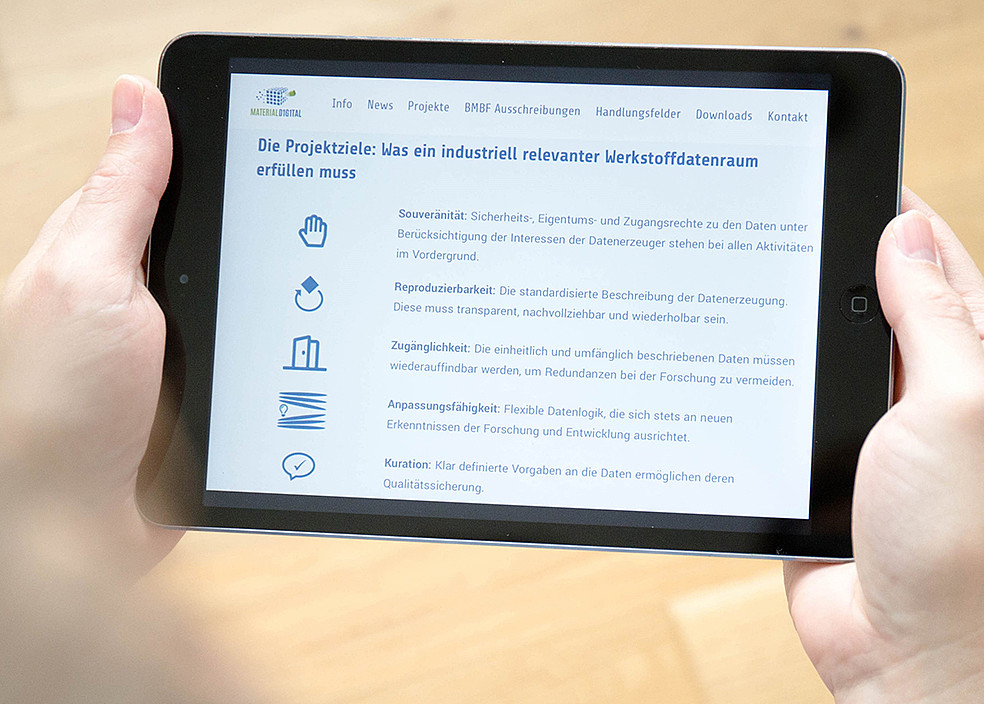

Two years ago, the kick-off for 'Innovation Platform MaterialDigital' took place, which was initialized by the German Federal Ministry of Education and Research (BMBF). Members of the MaterialDigital consortium are KIT and four other scientific and educational institutions as well as two institutions as associated partners. With the regular involvement of an experienced group of industry consultants, the team is working on the development of a digital material data space. With the help of it, data will receive a better structure and thus will be made machine-readable and -understandable. Additionally, MaterialDigital has set itself the goal of developing a consistent standard in material digitalization. The optimized materials and consistent standard are intended to reduce costs for companies long term and at the same time make industry in Germany more competitive.

Reaching consensus through discourse

To be able to achieve these goals, Dr. Fliegl and the cooperation partners are relying on the establishment of a material digitalization community: "Good networking is essential for the development of consistent standards. For this reason, we are working on establishing a scientific community to initiate fruitful discussions within it," explains Dr. Fliegl. Since the start of the project, the team has already been able to achieve initial successes through several initiatives: For example, the project website has met with lively interest since its initial launch and now counts more than 1,100 registered users and newsletter subscribers. The further development of a dedicated forum on the website will also be an important step toward transparent exchange with the community. Initial information events on BMBF calls for proposals within the context of MaterialDigital also achieved high visitor numbers. This provides researchers with valuable first feedback and confirms that the community has a positive attitude toward digitalization.

Using digitalized data to gain knowledge

In addition to community building, the researchers focus in particular on technical aspects, such as the development of a suitable platform infrastructure and the implementation of software tools and environments for digital workflows. Currently, MaterialDigital supports the workflow environments SimStack and Pyiron. These virtual environments serve the purpose of making various simulation sequences reproducible and making them easily available to users in the future. Another core task of the MaterialDigital platform is the development of ontologies. With the explicit and formal structuring, data following this logic can be stored, curated or even evaluated in a consistent way. The project team has already developed a core ontology for this purpose. "Ideally, we will eventually be able to couple this basis with artificial intelligence to gain new insights. However, that is currently still a vision of the future for us," says Dr. Fliegl. The 'Innovation Platform MaterialDigital' project will officially run until 2025. The German Federal Ministry of Education and Research explicitly wants the platform to be continued. A suitable business model is to be developed over the next few years.

comments about this article

No comments