Published on October 06, 2020

Asked #2: Interview with the nominees of the NEULAND Innovation Contest

* The order in which the short interviews are published is not an indication of placement in the contest.

What motivated you to take part in the NEULAND Innovative Contest?

Dr. Nanya Li: We have the desire to produce strong and lightweight composite components in a fast, simple and low cost way. The 3D printing assisted by microwave heating of continuous fiber reinforced composites is the best way to fulfill this desire. Our technology can fabricate complex lattice and bionic parts that can be used in aerospace, vehicles, sports and medical treatment. When we heard about the NEULAND Innovation Contest, we were thrilled by the idea. Participation offers us the chance to transfer research to business and connect to a network that contains countless excellent companies and industrial unities.

What do you want to achieve or improve with your technology?

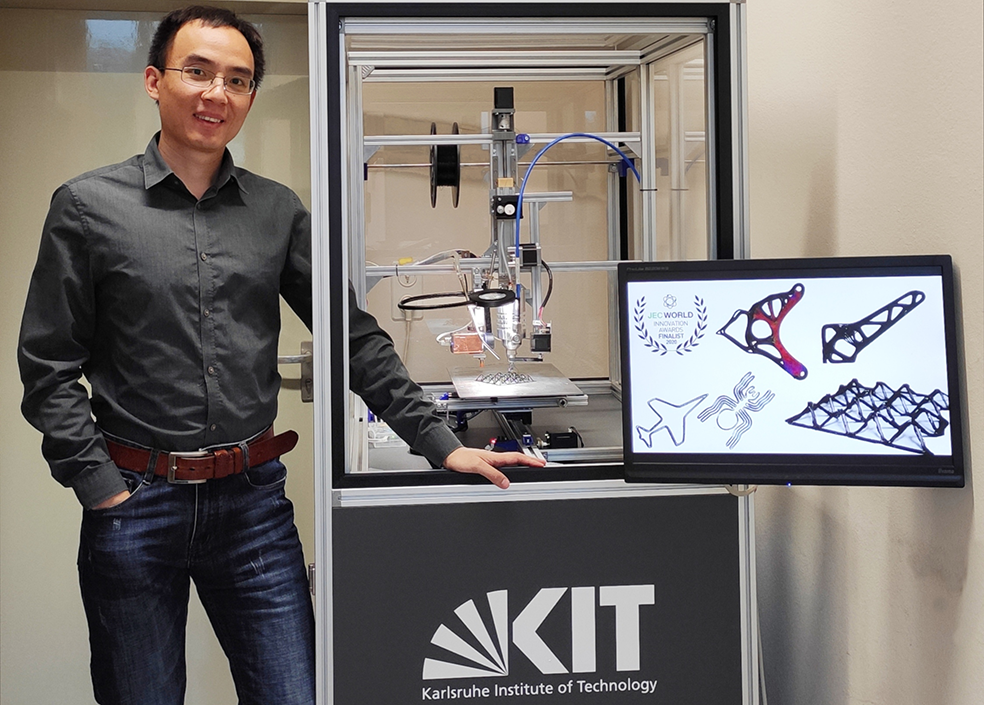

Dr. Nanya Li: As of today, we have developed an innovative prototype of 3D microwave printing systemcalled SERPENS (Super Efficient and Rapid Printing by Electromagnetic-heating Necessitated System). Many experiments have been conducted and several benchmarks have been verified by using this system. Compared to a conventional 3D printer, it can achieve production speeds at least ten times faster. The higher mechanical strength and larger printing amount are used for continuous fiber reinforced thermoplastic composites due to the selective and volumetric heating advantages of microwave. We plan to improve its performance by collaborating with industrial partners to enable mass production. The spin-offs generated from this technology also have enormous potential, such as compact printing head, CFRP filament production, load-dependent path planning and multiphysics printing simulation.

Who benefits from your idea?

Dr. Nanya Li: We believe that the lightweight industry, 3D printing, composite manufacturing and industrial microwaves can take advantage of our idea. We hope that various cases in our technology can be verified and that this innovative solution can bring social benefits and economic values.

What is the current status of your technology development? What has changed since the submission?

Dr. Nanya Li: Currently, SERPENS can manufacture complex topological optimized composites as well as the 3D free-standing lattice truss, both reinforced with continuous carbon fibers. With this technology we have won the 2020 JEC Innovation Award as a finalist and are now planning to bring it to the JEC exhibition in Paris next year.

Since the submission, the third generation of the microwave printing head with a smaller cavity and a rotatable nozzle has been installed and a new specialist control interface has been programmed.

What are the next steps in development?

Dr. Nanya Li: Next, we plan to scale the printing system to a larger dimension and use an industrial robot arm to produce more complex bionic lattice composites. Validation methods will be applied to further increase the printing speed and quality.

You have applied for a patent for your invention: Why did you protect your invention? With what intention or with what goal?

Dr. Nanya Li: To protect our working efforts, we applied for a German patent. Based on the review comments provided by the patent examiner, we are cooperating with the IRM department and have applied for an international PCT patent. The patent will be published after a few weeks. We hope that this patent can help us in the near future to transfer the technology or to share the market as a spin-off to establish a company.

The interview was conducted by Marie Simon.

Further exciting details on the printing process can be found in the technology offer: 3D microwave printer for continuous fiber-reinforced polymers.

comments about this article

No comments