Published on October 25, 2022

Humidity guard for agriculture

With a share of 70 percent, agriculture is the largest consumer of water by far worldwide. Soil humidity sensors can contribute to a more needs-based use of this scarce resource. So far, simple moisture sensors only measure how much water is available in the soil. Decisive for proper water management, however, is how much water the plants can actually draw from the soil with their roots. This absorption capacity, known among experts as soil water tension, depends strongly on the soil composition. Researchers at the Institute of Mechanical Process Engineering and Mechanics (MVM), together with TRUEBNER GmbH, have succeeded in developing an electronic soil humidity sensor – a so-called tensiometer – that masters this measurement variable. As part of a project at ‘KMU-innovativ’, the development partners have built a market-ready sensor consisting of a special porous ceramic disc and an electronic measuring unit.

Water march with system

In the course of global climate change, efficient water use becomes more and more pressing. Only through optimized irrigation strategies with the aid of modern monitoring and control methods can the available water resources be used sustainably. Especially irrigation in outdoor vegetable cultivation is characterized by an intensifying conflict of objectives between environmental protection and production. Water distribution technology has now reached a high level, but there is a lack of practical control systems with the appropriate measuring technology to determine the water status. In crop production, such as vegetables, grains or corn, farming operations have been unable to measure water balance adequately: Some commercial humidity sensors detect soil humidity through conductivity measurements. Thus, as more humidity is contained in the soil, the better the current is conducted. However, the water content is not sufficient as a measurement variable to obtain information about the soil water tension. Classic tensiometers determine the soil water tension by measuring the pressure in water-filled ceramic cells. But these are very maintenance-intensive, susceptible to frost and have only a limited measuring range. To overcome these disadvantages and to accurately measure whether the plants can draw enough water from the soil with their roots, the TRUEBNER company looked for new solutions.

Ceramic pores as analogy

The manufacturer of humidity sensors found suitable development partners at KIT: "The basic idea was to imitate the suction effect of plants by means of a porous ceramic. If the ceramic body is stuck in the soil next to the plants, the degree to which the pore-shaped cavities are filled with water allows conclusions about the suction tension of the soil," explains Prof. Dr. Norbert Willenbacher, who is specialized in the production of porous ceramics at MVM. The high porosity of ceramic disks enables a high water absorption - similar to a root - and thus a high measurement accuracy of the method. In this context, a broad pore size distribution ensures that water can be absorbed from a wide variety of soils and that the water available to plants can be determined practically independently of the soil composition. "We have invented a special procedure that enables the production of coarse-pored yet very resistant ceramics based on capillary suspensions," Willenbacher says. In this process, ceramic particles are suspended in a liquid. By adding a small amount of an unmiscible liquid, the result is a ceramic paste with special properties that, after shaping, drying and sintering, becomes a porous solid material that combines high porosity and high mechanical strength.

Ceramics from Capillary Suspensions

The basis for the production of porous ceramics is the use of so-called capillary suspensions, which consist of one solid and two non-mixable liquid materials. If a small amount of the second liquid is added to the suspension of solid and first liquid, a stable particle network is formed. This network is held together by the capillary forces created by the formation of liquid bridges at the contact points between the particles. This structure formation is accompanied by a change in the flow properties: depending on the kind and amount of the second liquid added, a pasty, shapeable material is formed, which can be processed using established techniques. After removal of the liquid components, for example by drying and following sintering, a molded part with a defined pore structure and high mechanical strength is produced. The process can also be used to produce plastic foams, e.g. for packaging or thermal insulation, with pores in the micrometer range.

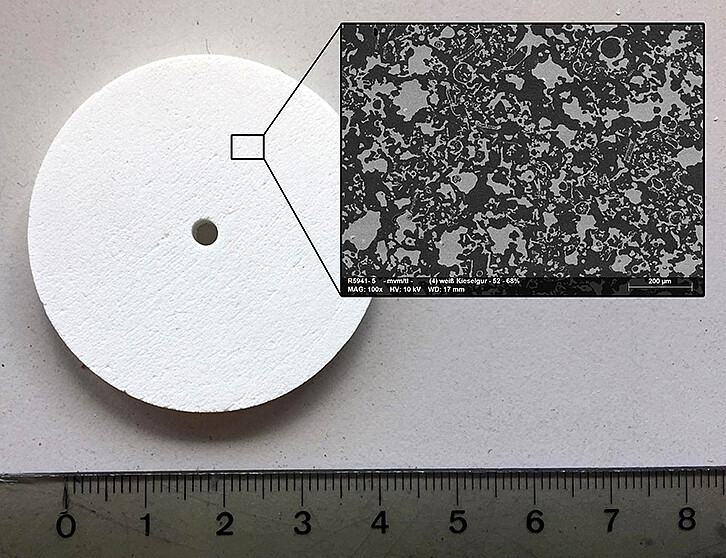

The fusion

David Menne from MVM worked on the ideal composition of the capillary suspension during his PhD in the project: "The challenge was to create a ceramic particle network that matches the application and works reliably in many different soil types. For this, we have conducted studies on the material composition from the necessary raw materials – such as particles, auxiliary fluids and binders – to obtain the desired ceramics." The result: highly porous ceramic discs with a diameter of about 50 millimeters and a height of 5 millimeters, which were combined with the also new electronic components of TRUEBNER GmbH.

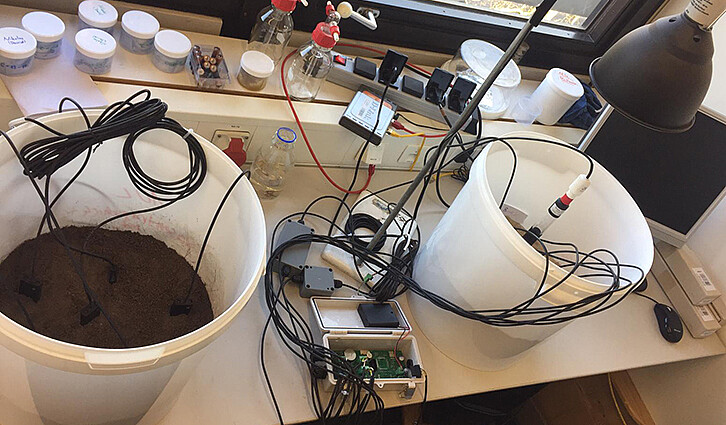

Ceramics and sensor technology are only successful in interaction: The porous ceramic discs absorb water from the soil. Depending on the present soil water tension, water is transported into or out of the measuring material. These proceedings are monitored electronically and provide a measure of how much water a plant can draw from the soil. With the aid of a wireless interface, the data can be transmitted directly without wires and, if necessary, connected to automated irrigation systems. It was particularly important to the project partner to develop a sensor that can determine the water available to plants in the subsoil in different soil layers at the same time.

Use in the field

As part of the project, the new sensors were tested in the field. Project member Menne reports: "After we had achieved satisfying results in the laboratory, we took the prototype of the soil humidity sensor out to cultivation fields throughout Germany. In cooperation with several agricultural companies, the sensor was used under real conditions, e.g. for the cultivation of blueberries, asparagus and tomatoes. We have collected important findings to once again improve the resilience and service life of the ceramics." With the reference measurements, TRUEBNER GmbH was able to improve the measuring sensitivity of the electronics and to test how the handling of the measuring devices works. The field tests and the response from the companies was very positive. The affirmation for TRUEBNER GmbH to include the novel Tensiometer in the product portfolio. The number of irrigated land is increasing worldwide. Here the new measuring technology helps to stop water wastage. In addition, there is further application potential in the research area around forest dryness and drought.

From project to business model

Prof. Willenbacher is not unfamiliar with the fact that a product or even a business model can grow out of scientific findings: "Good ideas should be transferred into applications. That's why I support the entrepreneurial spirit of my employees." The spin-off FastCast Ceramics will in future manufacture the ceramic discs in its role as a supplier. This ensures that TRUEBNER's customers will be supplied with a high-quality ceramic. For researcher Menne, the work in the project has thus become a perspective for the future: "Through my work at the institute and in the project, I was encouraged that the production of porous special ceramic parts has great potential. With my co-founders Moritz Weiß, Wolf Wedel and Johannes Käppeler, we are currently preparing the official company foundation."

comments about this article

No Comments