Superfine, robust, and low priced

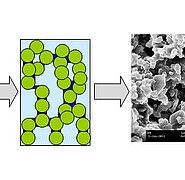

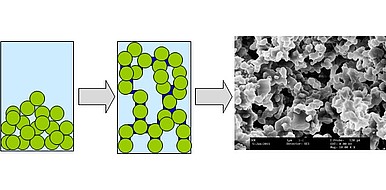

Porous ceramics are used as filters in water or waste gas treatment, as catalyst carriers and medical implant materials, and in various other applications. Conventional methods for porous-ceramics manufacture e.g., the replica technique or the placeholder method, in certain respects may have significant disadvantages for product manufacturing processes or material properties. Particularly very fine porous ceramics whose pores are smaller than ten micrometers can either not be manufactured at all using such techniques or else are of bad quality or cumbersome to fabricate. Moreover, there are further disadvantages e.g., increased production costs or toxic process gases, that maximize the demand for alternative production methods for macroporous ceramics. A new method developed by Institute for Mechanical Process Engineering and Mechanics (MVM) has the potential of enabling a low-cost, relatively simple manufacture of ceramics with pores sized 0.1 to 100 micrometers for the mass market. The method is based on the use of capillary suspensions consisting of one solid and two immiscible liquid or molten phases (e.g. aluminum oxide, wax, aqueous polymer solution). A robust particle network forms and flow properties start changing when a small portion of the second liquid is added to the suspension that consists of the solid and the first liquid phase. Depending on the type and quantity of the second liquid added, one obtains a robust, ductile material whose spacings are filled with the two liquids. After separation of the two liquid phases through debindering and subsequent sintering, one obtains a molded part with precisely shaped and defined pores. Industrial standard methods are used for the entire manufacturing process.It is also possible to manufacture plastic foams e.g., for packagings or thermal insulation as well as plastic membranes with pores in the micrometer range. Besides being used for manufacturing porous solids or membranes, the method can be applied to applications where hydrophilic particles must be dispersed permanently in a hydrophobic liquid or vice versa. MVM is looking for partners for further industrial development of the procedure described.

Images close open

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu