Solar cells with thermoplastic busbars

In order for the electrical energy generated in solar cells to be used, the cells must be metallized and connected to form modules. To do this, narrow contact lines – “fingers” – are applied to their front side, which collect the charges generated in the cell and transfer them to wider busbars. These current collection tracks conduct the electrical current to the module connections. Copper wire is used to connect the cells to modules.

State of the art

In conventional solar cell production, copper wires are soldered to the cells, which requires silver busbars. Solder pads are also needed to ensure a permanent mechanical connection between the cells. A large amount of silver is required for busbars and solder pads. The solar industry currently accounts for around 15 percent of global annual silver production, and this figure is rising sharply.

Technology

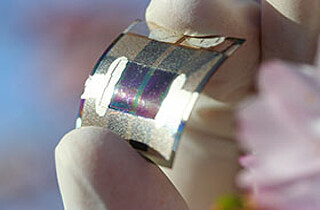

The Institute for Mechanical Process Engineering and Mechanics (MVM) at KIT has developed a technology that replaces busbars and solder pads with a thermoplastic, electrically conductive adhesive. This consists of a thermoplastic polymer with a melting temperature between 100 and 200 degrees Celsius and electrically conductive fillers such as graphite or silver-coated copper and glass particles. The adhesive is applied during the solar cell production process. In the subsequent stringing process, when several cells are arranged and connected to form a solar module, the adhesive can be returned to an adhesive state by heating. The copper wires can be pressed directly into this adhesive layer. After cooling, this creates an electrically conductive, mechanically stable cell-copper wire contact without the use of soldering materials.

Advantages

The process is suitable for use with both conventional high-temperature and innovative low-temperature solar cells. It aims to minimize the consumption of rare resources in production, simplifies manufacturing, and reduces costs. Repeated heating allows the wire and solar cell to be separated from each other, which simplifies recycling. The thermoplastic busbars can be applied using various techniques such as screen printing, dispensing, or filament printing, and production machines do not need to be converted.

Options for companies

KIT is seeking suitable partners from the solar production sector to implement this interconnection technology. The aim is to validate the process in real-world process environments.

Images close open

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu