Environmentally friendly organic solar cells

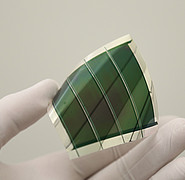

Solar cells based on organic semiconductors offer numerous advantages: they are mechanically flexible and lightweight, offer a high degree of design freedom and can also be manufactured in any color and shape. This makes organic solar cells suitable for mobile applications and for integration into facades, a variety of shades or even windows.

State of the Art

Organic solar cells are often manufactured using printing and coating processes in a large-scale roll-to-roll process. However, the solvents needed to produce semiconductor inks are often toxic or environmentally incompatible.

Technology

Researchers at the Lichttechnisches Institut (LTI) at KIT have therefore been looking for an approach that does not require toxic solvents. Instead of dissolving the organic semiconductors for the production of the semiconductor ink, they are dispersed in the form of nanoparticles in alcohol or other non-toxic media. The biggest challenge here is stabilizing the nanoparticles in the dispersion medium. Without further measures, the nanoparticles would stick together over time and precipitate out of the dispersion. To prevent this, the researchers mix another compound into the dispersion to electrically charge the nanoparticles. With this electrical doping, a targeted electrostatic stabilization of the introduced nanoparticles is achieved for the first time without negatively affecting the electronic function of the subsequent semiconductor layers.

Advantages

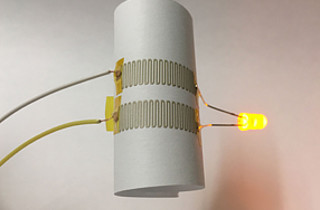

KIT's novel process for stabilizing semiconductor nanoparticles in printable inks enables, on the one hand, more environmentally friendly production and, on the other hand, expands the range of available organic semiconductors in printing and coating processes. The process is being continuously optimized in order to be able to process even more semiconductors in the future and thus expand the range of applications to other components, such as organic light-emitting diodes or printed electronics in the broadest sense.

Options for companies

The production of organic nanoparticulate semiconductor inks for printing environmentally friendly solar cells is ready for series production. For industrial application, KIT is looking for companies for the scaling of the manufacturing process and the use of the nanoparticulate semiconductor inks.

Your contact person for this offer

Innovation Manager Energy Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25335

Email: pelisson-schecker@kit.edu