Functionalization of parylene surfaces with UV

From waterproof outdoor jackets to dirt-repellent ceramics, coated surfaces are ubiquitous. Almost any substrate, such as metal, glass, paper, paint, plastic, ceramic or silicone, can be coated.

State of the art

Chemical vapor deposition (CVD) is an established and versatile process for surface modification using polymer coatings. In this process, objects are exposed to gaseous reactive precursor molecules under reduced pressure, which polymerize on the surface after thermal activation. This results in wafer-thin coatings that offer an extraordinarily high level of protection against chemical attack, environmental and ageing influences.

Technology

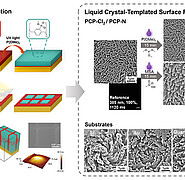

Researchers at the Institute of Functional Interfaces (IFG) at KIT have now succeeded in equipping parylene C coatings (based on paracyclophane), which are already widely used in industry, with completely new functional groups using a photochemical mechanism. The chemical, solvent-free transformation is catalyzed by UV light, whereby no additional catalysts, bases or other redox systems and no high temperatures are required. The phosphonate-containing parylenes produced in this way for the first time enable simple coatings through to targeted micro-fine network or fiber structures. All the structures created are characterized by high thermal and oxidative stability.

Range of applications

The range of potential applications is enormous. However, two are particularly promising: firstly, the new process can be used to create special biomedical coatings. For example, implants can be coated in such a way that they are not only antibacterial, but also have a growth-stimulating effect on the bone.

On the other hand, it offers great potential for optoelectronics: photolithography can be used to achieve extremely selective, defined topographical effects. With a photomask, the reaction takes place precisely and only in the exposed areas. The UV treatment not only changes the function and optical properties of the polymer film, but also increases its layer thickness. This allows the finest structures to be created in a targeted manner – even fluorescent if required.

Options for companies

Desired partners for future collaborations are manufacturers of medical technology and optoelectronic products in order to jointly optimize the biomimetic and structure-building potential of the new, high-temperature-stable process and bring it into industrial application.

Images close open

Your contact person for this offer

Innovation Manager New Materials and Health Technologies Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-26107

Email: jan-niklas.bloetz@kit.edu