Biodegradable parylene coatings

Coatings made of poly-p-xylylene (parylene) have become established in medical technology, but also in other areas such as electrical engineering, because they are particularly chemically inert and well adherent. In the case of implants, stents, catheters or pacemakers, in addition to providing mechanical protection for the material or integrated electronics, they also act as a barrier to leaking substances for the body.

State of the Art

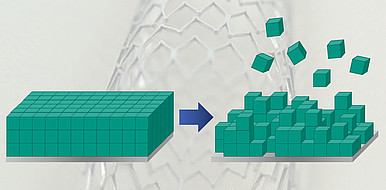

Solvent-based coating techniques, such as dip or spin coating, reach their limits in the biomedical field, as wetting problems and thus uneven layers or defects can occur with complex geometries. Therefore, in order to produce homogeneous permanent coatings, chemical vapor deposition (CVD polymerization) of parylene has become established, which is characterized by superior gap mobility. In this process, the starting molecules (precursors) are first sublimed in a vacuum system, pyrolyzed at high temperature and finally deposited on the desired object, on which they then react to form a solid polymer layer. Due to the nature of the process, no solvents are required and it is therefore particularly advantageous for coating sensitive materials.

Technology

Researchers at the Institute for Functional Interfaces (IFG) at KIT have succeeded for the first time in producing a new class of degradable parylene coatings by CVD polymerization. For this purpose, the researchers introduce a special co-monomer (cyclic ketene acetal) into the process, whereby degradable carboxylic acid groups are incorporated into the polymer chains. The rate of degradation can be regulated via the composition and is accelerated by hydrophilic groups, for example. Biomolecules or drugs can be attached via additional functional side groups.

Advantages

The coatings produced in this way combine the attractive properties of degradability and chemical functionalization. Degradable properties pave the way for even broader applicability of parylene coatings, e.g. in regenerative medicine as temporary biomedical coatings for resorbable implants.

Options for companies

Parylene thin films have shown in proof-of-concept that biodegradable temporary coatings are feasible. KIT is looking for partners for further development, such as in vivo studies and co-functionalization, and application beyond the field of medicine.

Images close open

Your contact person for this offer

Innovation Manager New Materials and Health Technologies Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-26107

Email: jan-niklas.bloetz@kit.edu