Robot with hand-arm model tests power tools

Hand-held power tools such as hammer drills, impact screwdrivers, or angle grinders are used on construction sites, for DIY, and also in the household. They are used by a wide variety of people: Professionals and amateurs, large and small, powerful and not so powerful. Companies have to consider this variance when developing their products.

State of the art

The forces applied to the tools by users during operation have a significant impact on the functionality and performance of power tools. For this reason, prototypes are subjected to stress tests that examine different force levels, behavior during machining of diverse materials, and working in different spatial directions. Until now, these have usually been performed manually by humans. Although the user bandwidth is represented by different test persons, it is difficult to perform one and the same work task in exactly the same way several times in succession. As a result, there is a wide variance in test results and great uncertainty due to individual influences.

Technology

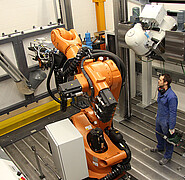

A test facility at the IPEK Institute for Product Engineering of KIT addresses these challenges in research. At the test bench, an industrial robot takes on the role of the test person. The special aspect: The robot is effect equivalent to a human being. A mechanical hand-arm model reproduces the dynamics, compliance, attenuation and inertia that act on the tool via the human musculoskeletal system. Thus, in the test, the same loads arise for the tool under test as if a human would guide it. However, different users and usage situations can be simulated in a targeted manner. The robot is fed with measurement data from a wide variety of people, which are scientifically investigated in advance with the aid of manual tests and a shaker system.

Advantages

Power tools can be tested on the robot test bench under variable but reproducible conditions. With fewer trial runs and great time savings, this produces less variance and more reproducible results than tests performed by humans. Device behavior in continuous operation as well as under extreme temperature influences is also explored.

Options for companies

Companies can use the test field for joint research projects with KIT to test their power tool prototypes in a research-driven manner and to improve ergonomics, performance, and force efficiency.

Images close open

Your contact person for this offer

Innovation Manager Mobility and Information Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25335

Email: julia.rast@kit.edu