Optimized controllability for ceramic composites

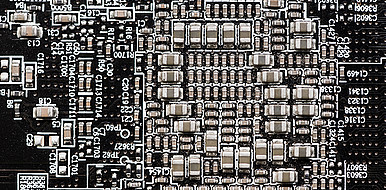

Ceramic composites have become an indispensable part of our industry. In electronic circuits, especially in microelectronics, the properties of ceramic materials ensure higher power tolerance with quasi-powerless control at the same time. Electronically controllable, the so-called functional ceramics enable, for example, phased array or reflect array antennas in radar and communication systems to be electronically pivoted by means of high-frequency phase shifters. Use in mobile communications or contactless sensor systems, such as RFID, is also feasible.

State of the Art

Ceramic composites, which have good electrical control, traditionally have high dielectric losses in the form of waste heat. This makes them inefficient and supplementary cooling systems may be necessary. Manufacturers of such composites must strike a balance between high controllability and low losses in the material composition for each application.

Technology

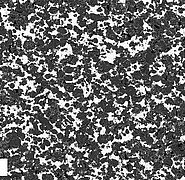

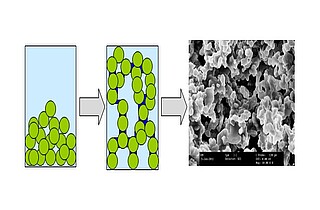

Researchers at the Institute for Applied Materials (IAM) have succeeded in improving the dielectric properties by selectively structuring the microstructure. In the newly developed process, the materials of the ceramic composite are not mixed uniformly as usual, but structured. The base materials magnesium borate (MBO) and barium strontium titanate (BST) are first pulverized individually by grinding, and MBO is additionally granulated. Mixed in different parts in a solution, MBO granules and BST powder produce a suspension which, by spray drying, yields a composite granulate consisting of MBO core and BST shell (core-shell). This granulate can be further processed by pressing or sintering. Clustering allows the proportion of MBO to be advantageously increased.

Advantages

The structure causes a redistribution of the electric field in the composite. This significantly increases controllability without simultaneously increasing dielectric losses. The material produced is applicable in a variety of high-frequency components up to about 10 gigahertz, such as controllable capacitors and tunable filters based on them, as well as adaptive impedance matching networks or phase shifters for electronic-pivot antennas.

Options for companies

The structured ceramic composite of MBO and BST was characterized at the institute in different compositions. On the one hand, KIT is looking for practical partners for the application, on the other hand for partners who can realize the production in an industrial environment.

Images close open

Your contact person for this offer

Innovation Manager New Materials and Health Technologies Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-26107

Email: jan-niklas.bloetz@kit.edu