Strong polymers for stronger accumulators

Due to their high energy density, lithium-ion batteries are suitable for use in portable devices such as smartphones or notebooks. Nowadays, they are also applied in other areas, for example to power electric vehicles or as stationary storage systems. Properties such as charge time, efficiency, voltage and lifespan of the battery can be modified by the use of selected materials and be adapted to the specific application.

State of the art

During charge and discharge of a battery cell, lithium ions move as charge carriers between the electrodes through the electrolyte. In order to prevent short circuits, the electrodes are spatially and electrically isolated from each other by a separator, which is permeable for lithium ions. In many cases, micro-porous polymer membranes are used for this purpose. However, if the cells are overcharged or exposed to high temperatures, the polymer separators become deformed. Subsequently, the electrodes may come into direct contact with each other, causing a short circuit and, in the worst case, leading to a thermal runaway of the battery.

Technology

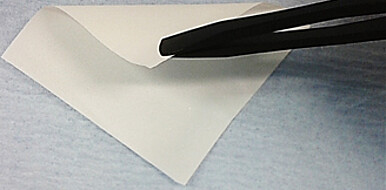

At KIT Helmholtz Institute Ulm (HIU), scientists have developed a novel separator membrane for lithium-ion batteries consisting of water-soluble polymers and inorganic particles: HTSep – High Temperature Stable Separator for lithium-ion batteries. For preparing the separator, guaran, or guar gum, a polysaccharide gained from the guar bean, is dissolved in water, and silicon dioxide is subsequently added. The resulting suspension is deprived of water in several stages by means of heat and transformed into micrometer-thin membranes, which are both mechanically and thermally more stable than previously used separators.

Advantages

Even in the event of overcharge and in case of temperatures of up to 180 degrees Celsius, physical contact between the electrodes is prevented. In addition, the separator demonstrates good wetting behaviour when brought into contact with liquid electrolytes. These improvements result in lithium-ion cells with a high cycle stability and a longer lifespan. The raw materials can be processed simply and inexpensively – furthermore they are environmentally compatible.

Options for companies

KIT is looking for industrial partners in the field of battery manufacturing for licensing of the technology.

Your contact person for this offer

Innovation Manager Energy Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone:

Email: transfer@irm.kit.edu