More efficiency through light

Efficient energy storage devices are in constantly growing demand. Lithium-ion batteries in particular are of key significance to progress in electro-mobility and to the stationary storage of energy. Therefore, one of the aims of research is to enhance the capacity of accumulators.

State of the art

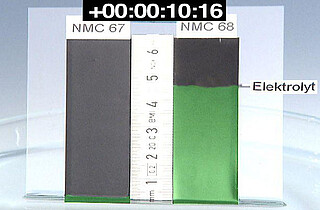

Usually, the electrodes of lithium-ion batteries consist of a current conductor and the substances involved in the reaction, the active matter. The cathode normally incorporates an aluminium foil as a current conductor, while the anode has a copper foil for this purpose. Layers of graphite can be used as active matter for the anode. The efficiency of a battery depends on a sufficient mechanical and electrical link between the active particles and the current collector. Insufficient bonding can result in the layers becoming detached and in battery failure.

Technology

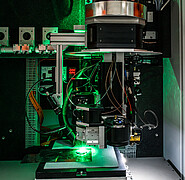

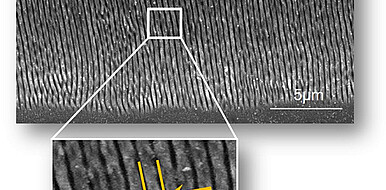

KIT researchers at the Institute for Applied Materials (IAM) have now developed a method to optimise the surface structures of the current conductor foils for bonding with the active matter. With the aid of short-impulse laser irradiation, nanostructures are created on the surfaces. The modified structure significantly enhances layer adhesion, and the active matter is firmly bonded with the current conductor. In addition, thanks to there being no need for mechanical or chemical roughening of the surface, thinner foils can be used, which means that the battery will then contain less inactive matter. The advantages are that battery performance is significantly raised by increased energy density, and that it will have a longer life since electrical resistance and the danger of layers becoming detached are clearly reduced.

Advantages

This procedure also enables the use of new materials for electrodes, such as silicon anodes, whose poor layer adhesion has so far not allowed their employment. All in all, the dry manufacturing process with laser rays requires no chemical solvents, which makes the production of batteries more environmentally friendly.

Options for companies

KIT is seeking partners for the further development and practical application of the technology.

Images close open

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu