Hybrid bonding

In metal construction, parts are usually joined by welding, screwing, and riveting. Metal construction elements, such as open rolled sections, hollow sections, and full cross sections, for instance, are joined in structural engineering, infrastructure development, and bridge construction. Conventional joining methods, however, have disadvantages: In case of screws and rivets, the component cross section is weakened by bores. Local energy input of welding adversely affects dimensional stability, robustness, and fatigue strength.

State of the art

Bonding allows components to be connected without these drawbacks. However, if bonding gap thicknesses of several millimeters or centimeters are required between the components to be joined due to unavoidable dimensional tolerances, conventional bonding cannot be applied. High costs of the bonding material and environmental impacts and work conditions on the construction site prevent the bonding technology from being used. At the KIT Research Center for Steel, Timber, and Masonry, scientists have now developed a hybrid bonding method for plug and lap points, thus eliminating the deficiencies of bonding in construction.

Technology

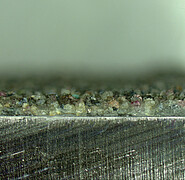

The new bonding technology consists of several layers: An organic bonding layer, inorganic granules, and mineral filler. Thin layers of chemically hardening structural bonding materials ensure adhesion to the component surface. The bonding material also seals the metal surface and protects it against corrosion. Bonding between the bonding layer and the filler material is achieved by a special, granular material dispersed on the bonding layer. These production steps can take place under controlled conditions at the manufacturer’s. Finally, bonding to the construction material is produced on the construction site using grout as filler material.

Advantages

Due to a combination of inorganic and organic bonding layers, the novel bond is of very high stability, while costs are reduced significantly.

Options for companies

At the KIT Research Center for Steel, Timber, and Masonry, high performance of this hybrid bonding technology was confirmed by extensive tests. KIT looks for cooperation partners to apply this new bonding technology and for pilot uses.

Images close open

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu