Direct synthesis of hydrogen peroxide

Hydrogen peroxide is an effective oxidant. It is used in a number of applications, in particular in chemical industry and paper production. Use of hydrogen peroxide results in the formation of water as the only by-product. Hence, it is considered an environmentally compatible oxidant.

State of the art

Today, hydrogen peroxide is mainly produced by the technically complex anthrachinone process. The process is based on a reduction of anthrachinone to anthrahydrochinone in the presence of a palladium catalyst. In the next stage, anthrahydrochinone is oxidized with oxygen to produce hydrogen peroxide and anthrachinone. This stage is followed by cleaning steps and the feedback of anthrachinone for another process cycle. Direct synthesis of hydrogen peroxide from hydrogen and oxygen was described in the early 20th century already. However, it has not yet been implemented on a large technical scale due to safety problems.

Technology

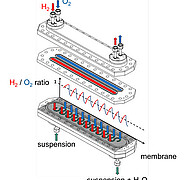

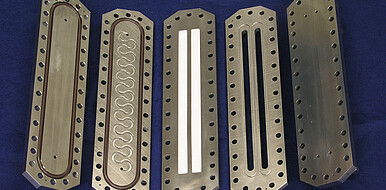

Scientists of the KIT Institute for Micro Process Engineering (IMVT) have now developed a microstructured reactor for the direct synthesis of hydrogen peroxide. The reaction takes place in a microchannel passed by a liquid solvent. A suitable solvent is water containing a suspended catalyst powder. Hydrogen and oxygen gases are fed into the liquid via membranes and consumed by the desired reaction to hydrogen peroxide. To achieve a high product yield, the gases are fed in repeatedly via several dosage points until saturation concentration is reached.

Advantages

The reactor is designed in a modular manner based on several layers of microstructured foils. Companies needing hydrogen peroxide may produce it flexibly, reliably, and in an environmentally friendly way using this microstructured reactor.

Options for companies

The KIT looks for partners for the use of the reactor in practice.

Images close open

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu