Dry battery electrodes efficiently and modularly

We encounter batteries and rechargeable batteries everywhere - from smartphones to cars. However, their production is not very sustainable and very energy-intensive. Around 50 percent of the energy is used just to dry the electrodes in which the electrochemical reactions take place. This is because the liquid that enables the paste to be coated has to come out again to make the batteries manageable.

State of the art

In convective drying, a warm air stream heats the goods to be dried and removes the moisture. Air, laser or infrared radiation are used for this. With conventional systems, it is usually only possible to find out which process parameters achieve the perfect drying result with time-consuming tests, as there is no sensory monitoring of the drying process. This results in large quantities of waste.

Technology

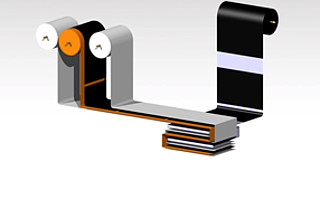

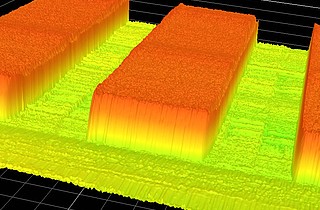

KIT researchers have succeeded in developing a modular dryer for battery electrodes. The design of the dryer hoods creates space that can be variably equipped with nozzles, emitters or sensors. The air is supplied via flexible hoses so that the nozzles can be positioned freely. Inline measurement technology monitors critical points in the drying process, such as the onset of pore emptying or the disintegration of the capillary network. Scattered light or thermal sensors such as pyrometers are used for this purpose. Changes in parameters, such as increased humidity, are compensated for during the drying process. The heat transfer coefficient can be measured and adjusted at each nozzle. This enables standardized, data-based drying. If the materials change, the set-up can be modified retrospectively.

Advantages

The advantages can be transferred to all industrial convection dryers. Set-up times are reduced as drying processes can be monitored by measurement and adjusted during drying. Waste is also reduced. The energy required is precisely metered using adjustable nozzles and used to best effect thanks to air circulation technology. The flexibility of the configuration enables rapid adaptation to new materials with different drying requirements. The technology is therefore not only sustainable but also future-proof.

Options for companies

The modular drying technology could be used in all areas of industrial drying. KIT is looking for partners for industrial development and pilot plant construction.

Your contact person for this offer

Innovation Manager Energy Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25335

Email: pelisson-schecker@kit.edu