Power Hardware-in-the-Loop as Real Lab for the Energy Transition

In progress of the energy transition renewable energies like wind and solar power and electrical traffic vehicles gain importance. Their sustainable use requires advanced grid technologies and powerful storage systems.

State of the Art

One challenge is the integration of new hardware components, such as batteries or battery-charging stations, into existing, often highly complex grid environments. To ensure smooth operation, all components must be linked and tested in advance. In the power hardware-in-the-loop (PHIL) process, the components to be tested are not directly integrated into the real system, but in a test facility with a virtual real-time system simulation. In this way, both real operating conditions and fault cases can be tested in a controlled environment.

Technology

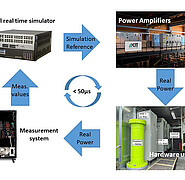

The Institute of Technical Physics (ITEP) of the KIT is running one of those solche PHIL-systems in the Energy Lab 2.0. New network components, network topologies and network technologies can be tested on the system in a virtual simulation environment in different operating modes. At 50 microsecond intervals, the simulator supplies the value for voltage or current at the point of the fictitious network where the test object is connected. This signal is sent to power amplifiers, which translate these values and output them as actual electrical quantities to the test object. The object under test, e.g. a battery-charging station for electric vehicles, thus "sees" a power grid from which it can draw power capability and feed it back. This power capability is measured and sent back to the real-time simulator, which takes it into account in the next computing step. The simulated grid thus reacts to the real test object and vice versa.

Advantages

The test scenarios are replicable to verify and validate results in this way. Complex operating situations can be quickly adapted digitally, so that test objects can be tested under changing conditions without great expenditure of time and money. New hardware products can be optimized in advance and brought to market faster. Interconnection with a solar field, methanization plant or power-to-liquid station is possible in the real laboratory.

Options for companies

KIT's PHIL simulation platform supports researchers, manufacturing companies, and system operators in analyzing, developing, and testing hardware future solutions for energy systems.

Images close open

Your contact person for this offer

Innovation Manager New Materials and Health Technologies Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-26107

Email: jan-niklas.bloetz@kit.edu