Performance checkup for Pedelecs

In recent years, there has been increasing demand for bicycles with electric assistance, or pedelecs for short. While the focus of development was initially on minimizing manufacturing costs, motorization, weight and performance data now play a decisive role for manufacturers and end users. As with electric cars, efficiency and range are expected to continue to increase.

State of the art

With a few exceptions, such as the R200 range test, there are hardly any test standards for pedelecs. In addition to manufacturer-specific test procedures, field tests are carried out: Cyclists cover a standard distance with the respective test bike and thus validate the technical parameters. However, person- and day-dependent fitness as well as deviating test conditions, such as environmental influences, make the results difficult to compare. Therefore, test stands with adjustable cadence and resistance offer better reproducibility.

Technology

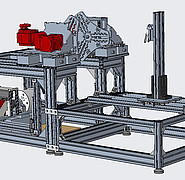

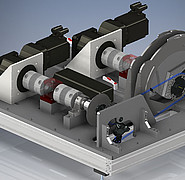

The Institute of Electrical Engineering (ETI) of KIT offers two such test benches for pedelecs. On the test stand of the complete system, the pedelec is fixed and operated on a roller as substrate. Two drive motors connected to the crank of the bike on both sides form an interface that can reproduce the treading behavior of a real cyclist and even a tensile load as with clipless pedals. Unlike known test stands, a torque (0 to 200 Newton meters) is applied to the drive. The roller runs at a speed of up to 45 kilometers per hour. With the aid of this test rig, fully automatic, realistic endurance tests can be carried out across the entire torque range. A second test bench allows the motor or drivetrain to be characterized as an individual component. In this way, electric motors can be tested at an early stage and with lower influencing factors, and different drive units can be compared with each other in terms of level of efficiency.

Advantages

With the help of the test parameters on the test benches, it is possible to simulate the complete operating range of a cyclist and to carry out driving cycles, operating ranges and support efficiency measurements. Due to the dual-side drive on the test bench, the driving behavior and acceleration of a cyclist can be simulated even more realistically and dynamically.

Options for companies

The test bench at KIT can be used beneficially in product development, in trouble shooting, and in the evaluation of existing products. The test facilities for pedelecs at KIT are available for industrial partners.

Images close open

Your contact person for this offer

Innovation Manager Mobility and Information Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25335

Email: julia.rast@kit.edu