Radiopaque coating for stents

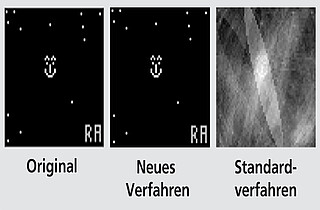

Health-threatening arterial occlusions and constrictions are treated with stents - small tubular grids made of nickel-titanium. As vascular support they keep the vessels open. Implantation, especially of stents with dimensions in the millimeter range, is often difficult. Due to their small size and material thickness, the stents are difficult to localize in X-ray images. However, exact positioning during the procedure is essential, as a correction is not possible afterwards.

State of the art

Currently, individual marker points made of heavy metals, such as tantalum or gold, are attached to the stents to increase the X-ray visibility. Heavy metals generally adsorb more X-rays, so that the mass contrast in the imaging is higher. However, the position of the stents in the vessel is not completely visible in this way, since only individual points are visible. The individual application of the contrast points is done manually by welding and is time-consuming and cost-intensive.

Technology

Scientists at the Institute of Applied Materials (IAM) have succeeded in increasing the X-ray visibility of stents with the help of a functional coating. Selected metallic materials of higher atomic numbers are applied to the stent as alloy layers via magnetron sputtering, up to a total layer thickness in the micrometer range. Due to the resulting higher radiopacity, stents can then be seen more clearly in the X-ray image.

Advantages

The selected material combination has good adhesion to the stent base material nickel-titanium. The coating can be applied to existing stent designs and tolerates elastic deformation. Stents coated with the new alloy allow a more reliable statement about the exact position of the stents - not only during invasive surgery, but also during medical monitoring and aftercare of the patient.

Options for companies

The alloy can be applied to almost all substrates. KIT is looking for partners for licensing or further development of the coating. Apart from medical technology, the absorbing effect could also be beneficially applied in other fields such as energy and electrical engineering.

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu