Pure white on polymer basis

Manufacturers of plastics, coatings and paints, as well as food, cosmetics and pharmaceuticals, colorize their products with different color pigments. A high degree of whiteness can be considered as a quality feature, especially in the case of white coloring.

State of the art

The mineral titanium dioxide has established as the standard pigment for white coloring. The reason: Due to the characteristically high refractive index of the titanium dioxide particles, incident light is almost completely reflected and appears in the processed product as a brilliant white surface, unless further color pigments are added. However, the metal oxide has been criticized because the nanoparticles or microparticles do not degrade and thus pollute the environment over the long term. There are also concerns that titanium dioxide could be carcinogenic.

Technology

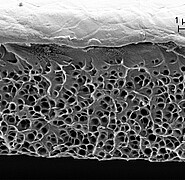

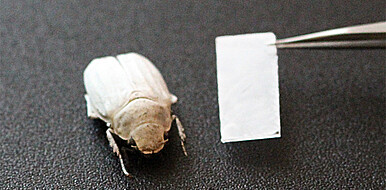

Scientists at the Institute of Microstructure Technology (IMT) at KIT are avoiding the use of pigments that are harmful to the environment and health by producing porous polymer structures with a comparably high refractive index. Depending on the required processing form - polymer film or powder - different process steps are used. The processes are biomimetically inspired by the white beetle Cyphochilus insulanus, whose surface appears white as a result of a special microstructure. According to its model, solid, porous microstructures, similar to a sponge, are produced from acrylic glass. The polymer films produced with this process can be industrially applied to different products, while the white polymer powders produced are mixed into a plastic matrix like pigments.

Advantages

The very thin but mechanically stable polymer structures are characterized by a high scattering efficiency and thus by a bright white appearance. The new technology enables a harmless, cost-effective white appearance and can be used on a wide variety of surfaces.

Options for companies

With only one starting material, different areas of application can be covered. The white polymer layers would also be suitable as a primer before the actual application of paint. The KIT is looking for partners for application-specific further development.

Images close open

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu