Seamless micro embossing of material webs

Microstructured surfaces have extended functional properties. This can, e.g. reduce the friction of highly stressed components in series production.

State of the art

The structuring is applied by wet chemical etching or ultrashort pulse lasers presently. However, these processes have disadvantages: they are partially harmful to the environment and become imprecise from a structure size of 10 micrometers. The laser processes in particular are also expensive and time-consuming.

Technology

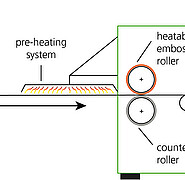

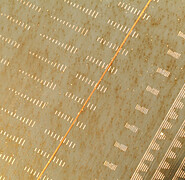

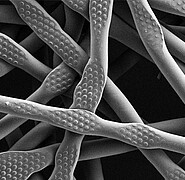

Scientists at the Institute of Microstructure Technology (IMT) at KIT have developed a mechanical roll-to-roll process for the microstructuring of polymer films or nonwovens, which enables continuous surface structuring by milling. The desired embossing pattern is first applied seamlessly to an embossing sleeve using the LIGA process (lithography, electroplating, molding) and a mask. The sleeve is then mounted on a roller and thus serves as embossing tool. Via the unwinder, the material web is led to the preheater and heated to a specific temperature. The pattern is then applied to the material web by the embossing roller with the help of a counter roller. Nonwovens are mechanically loosened and the embossing process is repeated. This enables hierarchical structuring when processing nonwovens. The roll-to-roll process allows different materials to be structured, e.g. thermoplastic nonwovens, standard and technical polymers or high-performance plastic films. This opens up new, diverse areas of possible applications.

Advantages

The mechanical process is more environmentally friendly than currently used chemical alternatives and can be applied for structure sizes below 5 micrometers. The seamless embossing sleeve allows a continuous embossing pattern without seam imprint. In addition, roll-to-roll embossing is suitable for large-area processing of material at high speeds and therefore suitable for industrial production.

Options for companies

A prototype demonstrating the seamless and hierarchical microstructuring of polypropylene fibres is provided at the Institute. The KIT is searching for partners for possible cooperations or further process development.

Images close open

Your contact person for this offer

Innovation Manager New Materials and Health Technologies Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-26107

Email: jan-niklas.bloetz@kit.edu