Simulate atomization at multiple scales

The flow of liquids and gases plays a decisive role in numerous processes. One example is gasoline and diesel injection in internal combustion engines, which significantly influences the formation of environmentally harmful nitrogen oxides and soot. Engineers and product developers are therefore constantly researching the optimum flow for specific applications.

State of the art

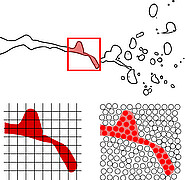

Computer-aided simulations of such flows support this development work considerably. Currently, mainly grid-based simulation methods are used for this purpose, in which the phases - liquid or gaseous materials - are represented as volume fractions in grid structures. In complex problems, such as fuel injection, the grid has to be moved along with the interface between liquid and gas, which requires enormous computing power. For technically relevant multiphase flows, this methodology reaches its limits.

Technology

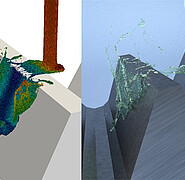

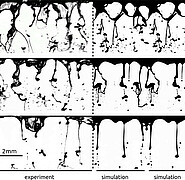

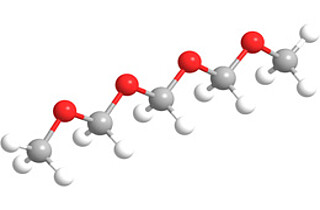

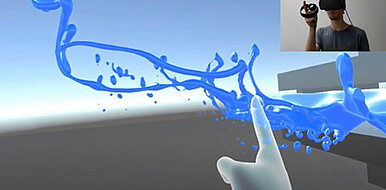

Scientists of the Institute of Thermal Turbomachinery (ITS) at KIT have chosen an extended approach. They have developed a simulation method based on the numerical procedure "Smoothed Particle Hydrodynamics" (SPH). In this method, fluids and gases are divided into mass packages – called particles – which move according to the laws of fluid mechanics. Through the movement and interaction of individual particles, flow fields can be simulated realistically. Due to the "grid freedom", complicated boundaries and interfaces that are subject to strong deformation can be easily realized. Currently, the method is used to simulate and optimize fuel injection nozzles of aircraft engines.

Advantages

Based on this approach, a virtual test bench has been developed that includes all important steps of flow simulation: from the preparation of the CAD data of the injection nozzle in preprocessing to the computation of the flow and visualization in postprocessing. In addition to common animations, the simulation results can also be viewed and manipulated from all possible perspectives by means of immersive virtual reality.

Options for companies

KIT is looking for industrial companies that want to use the SPH simulation technology for their own specific problems. Typical use cases are atomization, the wetting of surfaces with a liquid (sprays), and the interaction of liquids with moving components (oil lubrication).

Images close open

Your contact person for this offer

Innovation Manager Mobility and Information Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25335

Email: julia.rast@kit.edu