A reusable oil trap

Even today, removing oil from bodies of water is still a technical challenge. Solutions are lacking to get rid of the pollutants without leaving any remnants and to do so in an environmentally friendly and economical manner. In addition to high-sea oil-spillage disasters, small amounts of oil in industrial and private surroundings can already cause problems, as e.g. in the case of polluted cooling water, wastewater or pond water.

State of the art

Dispersing agents, sorbents or skimmers are familiar methods to get rid of oil spillages. However, they do not meet all the environmental protection and usability requirements. Disadvantages include incomplete cleansing, severe environmental pollution, a high disposal and cost effort or a lack of reusability.

Technology

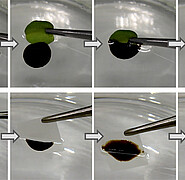

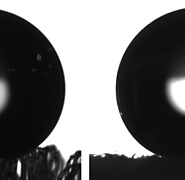

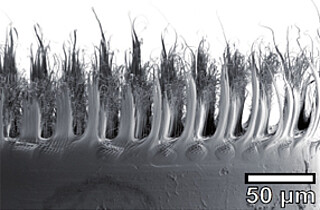

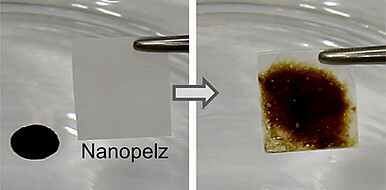

Scientists at the KIT Institute of Microstructure Technology (IMT) have developed a reusable foil with which oil can be selectively removed from water without harming the environment and in a continuous process. A plastic foil structured through heat extrusion and based on the surface of the Salvinia water fern forms the foundation for the oil absorber. Minute micro-hairs and cavities between them on the surface maintain an oil-attracting and water-repelling effect. Fixed to a system with rollers or bands, the foil can be immersed in a mixture of oil and water. The microstructures bind the oil to the foil and are subsequently pressed together so strongly that the oil collected can be emitted and captured. Once the oil has been pressed out, the foil, consisting of shape memory polymer, can be heated and brought back to its original shape, and the cycle can start off again. The foil can be reused without any chemical treatment, so that no waste products or harmful substances are created.

Advantages

A further design variant allows the foil to be used as a filter, as well. Holes in the foil will let either oil or water flow through them, whereas the respective other liquid is retained by the structures.

Options for companies

KIT is looking for partners to advance the technology and upscale it to a roll-to-roll production process for plastic foils.

Images close open

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu