Coiled to cut out short-circuiting

The energy turnaround is putting greater demands not only on power generation but also on transformer technology and the power grids themselves. Electricity from different sources and in strongly fluctuating quantities is fed into the central grid, which raises strain and requires higher performance density. Transformers are there to transform currents and voltages, coupling different branches of the grid and thus forming an important element of power infrastructure.

State of the art

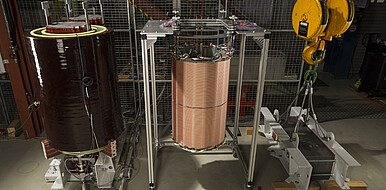

Conventionally, transformers with copper or aluminium coils are used that are air- or oil-cooled. This results in a higher material effort for coil construction and greater danger in the event of a fire. New developments are therefore oriented on superconducting coil material in order to build more compact and efficient transformers. Superconductors have a particularly high current carrying capacity, and when overcurrents occur, they demonstrate a current-limiting effect caused by a rapid increase in electric resistance. This increase in resistance limits short-circuit currents.

Technology

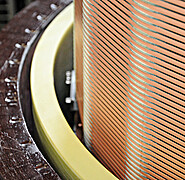

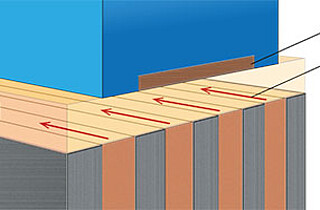

Researchers at the Institute for Technical Physics (ITEP) have developed an optimised concept. The novel coil body consists of several equally formed individual components that form a load-bearing surface around a supporting pipe with their plug-in connections. These components can be produced at a low price using industrial standard processes such as injection moulding. The composite surface forms grooves and longitudinal bulges and depressions. The superconductor bands are wound over the bulges, and the grooves ensure defined positioning. The gaps that develop between the superconductors and the coil body enable cooling with liquid nitrogen around the super-conductors, while the conductor material can expand in the depressions if there are thermic changes owing to short-circuiting.

Advantages

Integrated current limiting and the supporting coil protect transformers and grid components from overcurrent and damage if short circuits occur.

Options for companies

KIT is looking for partners seeking to advance and apply the technology.

Images close open

Your contact person for this offer

Innovation Manager New Materials and Health Technologies Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-26107

Email: jan-niklas.bloetz@kit.edu