Directing currents in heat exchangers

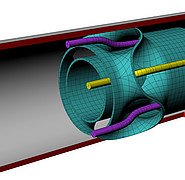

It makes sense to use heat exchangers in many processes in which heat develops as a by-product. Here, unused thermal energy is utilised with the aid of heat transfer. Released heat energy moves to a liquid, such as water, in a cooling circuit. The coolant is then guided past at least one flow passage. Via the heat conductive wall of the passage, heat is thus transferred from the warmer to the cooler medium. Waste heat is transferred and can be further used, for example in a heating system. Scientists at the KIT Institute for Micro Process Engineering (IMVT) have developed special, micro-structured flow guiding elements with which pipe-in-pipe heat exchangers can be operated even more efficiently. Two pipes, one inserted into the other, that serve as pressure vessels are fitted with the flow guiding elements – each of them in the inner pipe and in the annular gap between the outer and the inner pipe. The metal guiding elements are printed in 3D using selective laser melting and put in the flow passages, into which they fit perfectly. Two fluid currents of different temperatures are fed into the thus prepared pipes in opposite directions. The geometry of the guiding elements developed at KIT is crucial to the highly efficient heat transfer. It splits the fluid current into a random number of sub-currents that flow past one another in a controlled manner. Since the individual sub-currents are led up and down, during flow progression, they come into contact with the passage wall and also, several times, with the other sub-currents, without mixing with them. After each contact with the passage wall, the temperature of a sub-current evens out in the course of flow progression within the guiding element, with the defined current ensuring optimum heat transfer, so that thermal efficiency is considerably higher. All in all, this allows the use of a reduced-size heat exchanger. Thanks to the temperature-regulating effect, the flow guiding elements can also be used for process tempering in order to maintain a certain operating temperature. KIT is looking for users interested in applying the elements as well as collaborative partners to advance the technology.

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu