Controlling turbulences

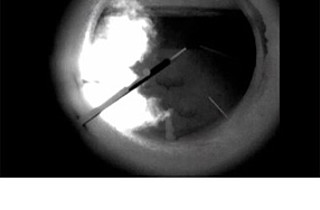

Modern combustion plants, such as gas turbine combustion chambers, are operated under low-fuel condition in order to largely prevent the formation of nitrogen oxides. Under these conditions, combustion instabilities occur frequently, which result in oscillations in the combustion chamber. These oscillations do not only cause a high noise level in the surroundings of the plant, but also accelerate wear of the turbine. During combustion with a turbulent flame, the heat release rate has a significant influence on the unstable operation states in the chamber. The heat release rate, however, cannot be measured easily. Alternatively, chemoluminescence of hydroxyl radicals (OH*) is measured, as it is closely related to the heat release rate. Chemoluminescence is measured by means of an optical tomography method. Due to rapid fluctuations of the turbulent combustion process, the measurement has to be accomplished with a high spatial and temporal resolution, which cannot be achieved with conventional tomography methods due to the small OH* concentration of 1-10 parts per billion. Scientists from the Institute for Chemical Technology and Polymer Chemistry and the Engler-Bunte Institute have developed a tomography method that generates a reliable sectional view within about 100 µs. Instead of rotating an individual measurement head around the measurement object as in classical nuclear magnetic resonance tomography, several telescopes are arranged under certain angles to the flame. Each of these telescopes contains 90 light fibers that are combined into a light fiber cable and transmit the measured chemoluminescence signals to an individual intensified CCD camera. To reconstruct the flame cross section, it is done without the usually applied methods of filtered back projection. Instead, methods based on self-consistency are applied. The latter reproduce the spatial distribution of chemoluminescence much more precisely than those based on filtered back projection. By the use of the new tomography method, the combustion process can be monitored constantly in an online manner and controlled by varying the fuel supply.

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu