Measuring device for stress states in textiles

Wherever soft and flat textiles or films are stretched over three-dimensional shapes, tension and distortion occur in the material, which can lead to wrinkling. In the case of car seats, upholstered furniture or umbrellas, this may simply look unattractive. In the case of textile structures, parachutes or balloons, however, this can impair the load-bearing behavior. Manufacturing companies want to avoid both.

State of the art

To find out whether a fabric is suitable for stretching in space or for covering a certain three-dimensional shape – i.e. whether it will neither tear nor wrinkle – there is usually no other option than to test its tension behavior on scale models. Just as fashion designers test the desired drape of fabrics on dressmakers' dummies, only in reverse. This is time-consuming and cost-intensive, which is why manufacturers usually use empirical values of common materials.

Technology

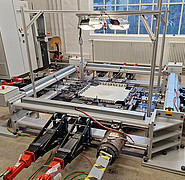

Researchers at the Institute of Design and Structural Engineering at KIT have invented a measuring device that can be used to simulate stress states caused by spatial shapes in flat textiles or foils on the surface. For this purpose, the samples are clamped in a square and kinematic structure. Using three movable drives on each of the four sides, any normal and shear stresses can be induced and also changed during the test. A load, a displacement path or a loading speed are specified in order to obtain stresses and distortions or roughness in the specimen via a biaxial tensile test. A camera mounted above the test device repeatedly photographs a spray pattern applied to the material and thus makes the distortions visible.

Advantages

The great added value of the measuring device is that the material parameters can be determined in a single test sequence. In similar existing devices, separate test setups had to be created in order to determine the transverse strain, stiffness modulus, shear modulus and biaxial tensile strength of a material. In addition to the time and cost savings, the specimens are easy to install and remove and the results are more precise.

Options for companies

The KIT offers test runs on the measuring device as a service for material manufacturers, particularly for uncoated and coated fabrics and films. Partners are also being sought for the transfer to series production.

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu