Technology Offers

Search by categories

Thermal validation with dummy battery cell

A battery cell model from KIT enables safe and efficient thermal evaluation of battery systems under real conditions.

- Aerospace industry

- Automotive industry

- Electrical engineering

- Energy and water supply

- Energy technology

- Measurement technology

- Mechanical engineering

- Process and production engineering

- Automation / IT

- Simulation and data processing

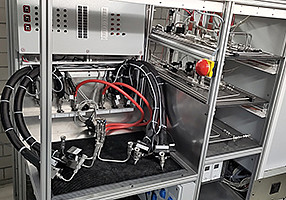

Performance test for fuel cell systems

A new KIT fuel cell test bench simplifies the testing of complete fuel cell systems with interchangeable subcomponents.

- Automotive industry

- Building industry

- Coating technology

- Aerospace industry

- Raw material and textile industry

- Polymer industry

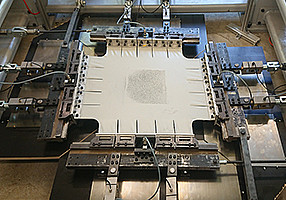

Measuring device for stress states in textiles

Biaxial test facility at KIT measures arbitrary stress and distortion states in flat membrane materials such as textiles and films.

- Plant engineering

- Drive technology

- Automotive industry

- Building industry

- Polymer industry

- Mechanical engineering

- Process and production engineering

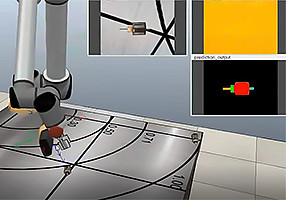

Inspecting surfaces with machine learning

A method has been developed at KIT to automatically evaluate surface states of objects using video images, neural networks, and machine learning. Intelligent surface inspection can improve defect inspection.

- Automotive industry

- Energy and water supply

- Energy technology

- Simulation and data processing

- Safety technology

- Environmental technology

- Automation / IT

- Services

- Measurement technology

- Electrical engineering

Power Hardware-in-the-Loop as Real Lab for the Energy Transition

The Energy Lab 2.0 at KIT provides a virtual real-time simulation environment for testing power hardware components under real power grid conditions.

- Drive technology

- Automotive industry

- Mechanical engineering

- Process and production engineering

- Measurement technology

- Simulation and data processing

- Services

From vehicle noise to warning system

KIT researchers analyse, how mobility caused noise and sound affect humans. Research is also being conducted on the chassis dynamometer to find out how the car of the future may sound.

- Automotive industry

- Aerospace industry

- Mechanical engineering

- Plant engineering

- Process and production engineering

- Building industry

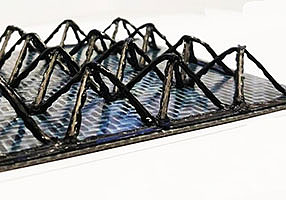

XFRP springs with variable fiber combination

Springs made of a new type of fiber-plastic composite increase reversible energy absorption capacity through special combination and arrangement of the fiber materials.

- Automotive industry

- Drive technology

- Automation / IT

- Measurement technology

- Simulation and data processing

- Safety technology

- Services

- Analytics

Automobiles on the test bench

KIT's vehicle-in-the-loop test bench enables continuous, close-to-reality vehicle tests, considering the interaction with the driver and the environment.

- Aerospace industry

- Automotive industry

- Measurement technology

- Electrical engineering

- Environmental technology

- Forestry and agriculture

- Communication and data transmission

- Safety technology

Transmit signal separation for MIMO radars

Optimized MIMO technology improves resolution and dynamics for sensor networks for remote sensing and surveillance.

- Plant engineering

- Automotive industry

- Printing industry

- Polymer industry

- Process and production engineering

- Aerospace industry

3D microwave printer for continuous fiber reinforced polymer

A new system for additive manufacturing by using microwave heating to print components made of continuous fiber reinforced composites quickly and efficiently.