Technology Offers

Search by categories

With biohybrid composite material to 3D cell culture model

KIT has developed a unique process to produce customized three-dimensional composite materials for the coating of culture vessels. The biohybrid materials have precisely controllable mechanical properties.

- Coating technology

- Biotechnology

- Polymer industry

- Printing industry

- Medicine and healthcare

- Process and production engineering

Biodegradable parylene coatings

Surface modification with parylene coatings that are degradable for the first time opens up new uses for biomedical applications.

- Coating technology

- Printing industry

- Electrical engineering

- Energy technology

- Optical Industry

- Process and production engineering

- Chemical industry

Environmentally friendly organic solar cells

Novel process for producing semiconductor inks increases the environmental friendliness of solar cell production.

- Automotive industry

- Aerospace industry

- Mechanical engineering

- Plant engineering

- Process and production engineering

- Building industry

XFRP springs with variable fiber combination

Springs made of a new type of fiber-plastic composite increase reversible energy absorption capacity through special combination and arrangement of the fiber materials.

- Coating technology

- Polymer industry

- Process and production engineering

- Printing industry

- Microtechnology / precision mechanics

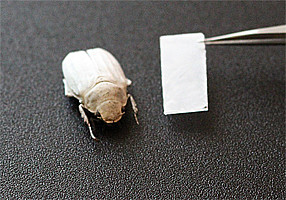

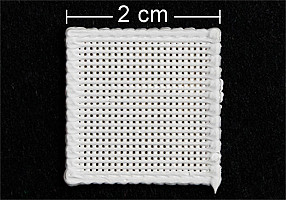

Pure white on polymer basis

Microstructured, porous polymer films and powders produce white coloration for industrial products as a non-toxic alternative to titanium dioxide.

- Ceramic industry

- Filter technology

- Chemical industry

- Pharmaceutical industry

- Process and production engineering

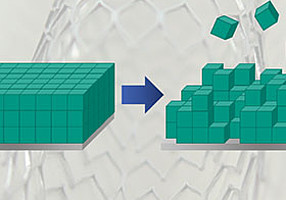

Highly porous ceramic filters from the printer

Novel ceramic pastes and a special drying method enable 3D printing of highly porous cellular ceramic filters.

- Energy technology

- Chemical industry

- Energy and water supply

- Coating technology

- Automotive industry

- Process and production engineering

A reinforcement for electrolytes

New class of materials consisting of filler-reinforced polymerised ionogels can be used as solid electrolyte membrane for lithium-ion batteries.