High-frequency sensor for non-contact torque measurements

Torque measurements are carried out, amongst others, in vehicles and industrial machines, in order to mutually coordinate dynamic processes, and therefore, to ensure high effectiveness and control.

State of the art

Non-contact measurement by sensors on magnetic basis is widely used. However, there is an increased technical effort because additional signal lines have to be employed for a measurement procedure. These extra elements require a lot of installation space, which makes their use for serial products more difficult and expensive.

Technology

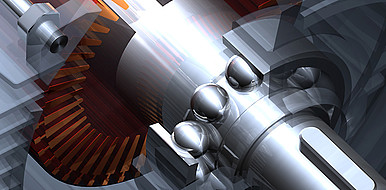

Scientists at the Institute for Applied Materials (IAM) at KIT developed a novel sensor setup for non-contact torque measurements. It consists of a ferromagnetic film material on a, e.g. rotating shaft and a high-frequency measuring head represented by a triplate strip-line. First, the ferromagnetic film on a substrate as a film sensor has to be conditioned, i.e., a preferred magnetic direction has to be induced, and is then mounted on the shaft. The measuring head is located closely above the film sensor and represents a contactless measurement technique. Due to the high-frequency field emitted by the strip-line, ferromagnetic resonance is excited in the film sensor. If there is a torque or change of torque, it generates stress in the shaft and transfers it to the film. This changes the ferromagnetic resonance frequency. The strip-line detects a signal and reflects it as a ferromagnetic resonance shift. Calibration enables a direct relation to torque.

Advantages

Since the torque is directly related to the ferromagnetic resonance frequency shift, reflection measurements can be carried out with only one high-frequency signal line and without any additional technical effort. In addition, the individual components are inexpensive and space-saving, so that a low installation weight is achieved and costs can be reduced.

Options for companies

Various laboratory setups for static measurements have already been implemented and dynamic measurements will be tested. KIT is looking for partners for an advanced development of this technology.

Your contact person for this offer

Innovation Manager Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25587

Email: rainer.koerber@kit.edu