Adaptive gearbox for robots based on the human model

More and more often, robots are to be created that are similar to humans in terms of mobility and strength. But designers face major challenges. Natural muscles are powerful at low speeds and can only muster a small amount of force during fast movements. In order to correctly emulate such specific motion sequences, gears with variable transmission ratios are needed.

State of the Art

Common transmissions in robotics limit speed and maximum force, other conventional transmissions are complex and therefore too large for robotics applications. While human-like conditions can already be achieved with hydraulic systems, there are often problems with control and the risk for hydraulic oil leaks is high.

Technology

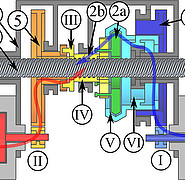

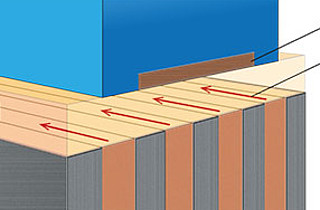

Researchers at the Institute for High-Performance Humanoid Technologies (H2T) of KIT have succeeded in designing a compact and inexpensive gearbox for linear drives with two gear ratio stages. The drive consists of two motors that combine the characteristics of a spindle drive and a cycloidal gearbox. In the spindle drive, a nut that slides over a spindle translates the motor rotation into linear motion. The gear ratio is determined only by the spindle pitch. When the second motor is used, the eccentrically mounted nut rolls over the spindle, so that the transmission ratio of the spindle is multiplied by the transmission ratio of the cycloidal gearbox. When both motors are engaged, the operating mode changes automatically (adaptively) depending on the external force applied to the spindle: If the force is high, the gear stage with a high ratio operates; if the force is low, the gear stage with a low ratio operates. This creates a force-speed ratio similar to that of humans.

Advantages

The new linear gear unit has a simple design, requires few special parts and can be installed in a very small space. Another advantage of the new design is that the electric motors are easy to control and clean. This combination makes the adaptive gear units particularly interesting for the "low-cost" sector.

Options for companies

With the help of the new technology, lighter and smaller robots can be constructed. If these are used as cobots, i.e. in the immediate vicinity of humans, the compact design increases safety in the event of collisions. KIT is looking for partners from the gear and motor manufacturing industries to bring the invention to series maturity.

Your contact person for this offer

Innovation Manager Mobility and Information Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-28460

Email: birgit.schulze@kit.edu