Test cell for solid-state batteries

Lithium-ion batteries with liquid electrolyte have so far been used primarily in small electronic devices, but are reaching their performance limits in electromobility. Solid-state batteries are a promising alternative: by eliminating liquid electrolytes, the risk of leakage and flammability is minimized. In order to find the ideal material combination for anode, cathode and electrolyte, the storage medium must be explored.

State of the art

For the necessary series of tests, various material combinations in the form of pellets are put into a cell casing and subjected to controlled charging and discharging cycles. Such a pellet must be enclosed in the casing under pressure in order to ensure contact between the solid state electrolyte and the electrodes even without a binding liquid. Up to now, only test cell casings exist that cannot simultaneously realize the exclusion of air, a defined contact pressure and a non-destructive removal, or can provide this only by means of a complex design. The pressure is often created by a frame, which makes the entire construction unwieldy and heavy. This makes them unsuitable for working in a climatic chamber as well as under a protective atmosphere.

Technology

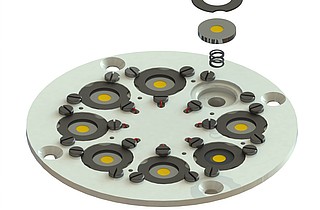

Scientists from the Institute for Applied Materials (IAM) at KIT have now developed a compact cell casing for electrochemical experiments on solid-state pellets. The cylindrical test cell made of stainless steel and temperature-resistant PEEK components allows the separate adjustment of pressure and sealing. The pellet is inserted into the cylinder and closed from above with a cover having an integrated piston. A cylinder screw is tightened with a torque wrench; the piston thus exerts a defined pressure on the pellet. The tightening of four more screws seals the cylinder with a sealing ring. Finally, electricity can be applied to the airtight cell casing.

Advantages

Due to the finely adjustable pressure application, tests can be carried out and reproduced under identical conditions. The results of different pellet compositions as well as cycling at different C-rates are thus comparable. The casing allows easy cleaning and removal of the pellets for follow-up tests.

Options for companies

In the institute laboratory, the cell casing has already been used for a longer period of time. KIT is looking for partners to manufacture the cell casing and to use it for battery testing.

Your contact person for this offer

Innovation Manager Energy Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25335

Email: pelisson-schecker@kit.edu