A reinforcement for electrolytes

Lithium-ion accumulators still belong to the most efficient electrochemical storage systems. They are characterised by a high specific energy content (energy per unit weight), which enables them to provide energy for portable devices with a high energy demand, such as tablets, power-tools or electric vehicles. Despite success scored so far, the aim is above that of significantly improving energy density, battery safety and cell performance.

State of the art

Although the liquid electrolytes that are currently used feature a high degree of ion conductivity, using them does bear disadvantages when they are in operation. Potential leakages and the danger of thermic runaway represent a safety risk. This risk can be effectively limited with solid electrolytes.

Technology

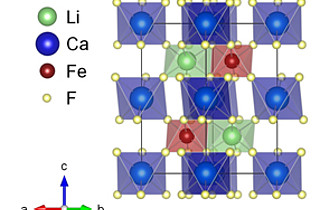

At the KIT Institute for Applied Materials (IAM), scientists have developed filler-reinforced polymers that could be used as solid electrolytes. This new class of materials is based on an ionic liquid containing acryl that ensures the mobility of the charge carriers. It is mixed with nano- to micro-scale, functionalised fillers and a lithium conductive salt. The viscose paste that is obtained in this manner and is also referred to as ionogel is homogenised and polymerised in a subsequent step, so that a direct chemical bonding between the ionic liquid and the filler is achieved and optimum mechanical stability is ensured.

Advantages

TAs a firmly bonded layer, the polymer can be employed as a solid electrolyte membrane. In addition, a large proportion of filler and the resulting strength protect the electrodes from dendrite growth. The material properties, such as conductivity, strength, dielectricity or elasticity, can be modified by the amount of filler in the mixture, which makes them applicable for a wide range of purposes, for example also outside lithium ion technology as condenser membranes. The new solid polymer membrane brings together the functionality of the electrolyte and the separator. This means that battery cells with a smaller volume can be realised.

Options for companies

KIT is looking for partners to advance and validate the ionogels.

Your contact person for this offer

Innovation Manager Energy Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25335

Email: pelisson-schecker@kit.edu