Chromatography under control

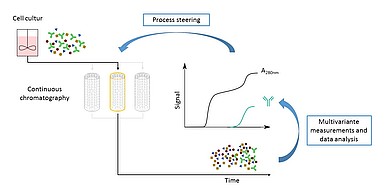

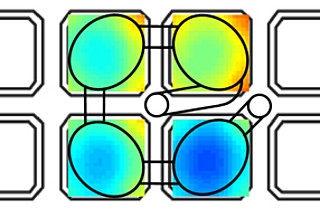

Nowadays, biopharmaceuticals such as drugs used in combating cancer are produced in cell cultures. In a subsequent step, the desired active agents have to be extracted. This filtration from the mixture of substances is accomplished with a number of elaborate separation methods for which chromatographic processes have been established. At the moment, a reversal is in progress from batch chromatography to continuous chromatography. Here, the mixture of substances is purified by several fixed-bed columns acting in concert (multicolumn chromatography). Continuous process control is essential, especially in continuous chromatography, where the biological processes of cultivation are subject to a high degree of variability.

State of the art

As yet, process monitoring is restricted to a small number of parameters, such as the pH value or absorption at a wavelength that are read as univariate signals with the aid of various measuring methods. This means that only one parameter can be measured by the detector at a time. The key quality characteristics such as the concentration of the target substances are only determined afterwards. Not only does this approach require a considerable time effort, but it can also result in inconsistencies in production only being detected later on and at worst entire batches having to be disposed of.

Technology

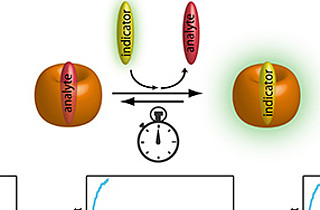

Scientists at the KIT Institute of Process Engineering in Life Sciences (BLT) have developed a process control method for column chromatography that can detect substances in a detailed form during purification. In contrast with the state of the art, the diode line detector with multivariate signals enables measuring many meaningful process attributes in parallel. The established values are evaluated in real time with the aid of mathematical models such as Partial Least Square Regression and enable conclusions to be drawn e.g. regarding concentration levels of the product or contaminants.

Advantages

This evaluation method allows early conclusions regarding the extraction of the target medium during the entire process, which enables individual process decision to be made to optimise chromatography.

Options for companies

KIT is looking for partners to advance this technology.

Your contact person for this offer

Innovation Manager New Materials, Climate and Environment Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-26107

Email: jan-niklas.bloetz@kit.edu