Highly concentrated measuring of molecules

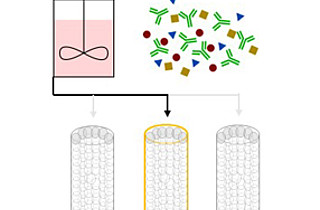

In biopharmaceutical process development, the concentration of protein and DNA samples is usually established with the aid of UV/Vis spectroscopy. The samples are examined using different wavelengths or the entire spectral range. The amino acids or nucleobases contained in the samples absorb these light rays and the measureable absorption provides information about the concentration of the sample examined.

State of the art

In order to be able to determine the concentration of the protein solutions in automated high-througput, these are transferred standardly into microtiter plates and measured in automated process lines. However, the use of these platforms entails interference factors. Technology only allows the measurement of protein concentrations in a certain absorption range, so that samples have to be diluted many times. This can result in measurement errors, especially for small volumes. A further disadvantage is that the surface tension of the samples causes a liquid meniscus (surface curvature) in each well of the plate. Among others, the intensity of meniscus formation depends on the protein concentration of the sample. This results additionally in inaccuracies when the measuring results are compared.

Technology

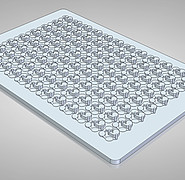

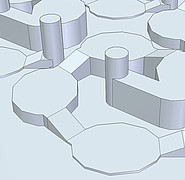

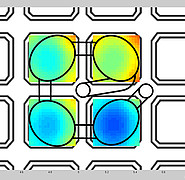

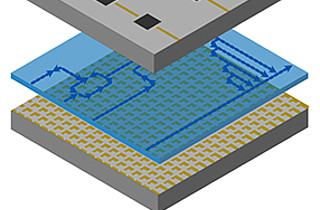

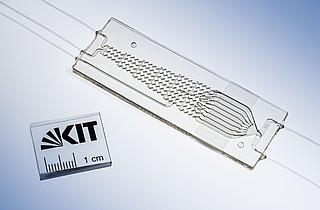

At the KIT Institute of Process Engineering in Life Sciences (BLT-MAB), scientists have developed a silicon-based microfluidic sample carrier that eliminates the influence of diluting and menisci at reduced sample volume levels and thus provides quantitatively and qualitatively high-value measurement results in a wide range of concentration (approx. between 0,1 and 100 milligrams per millilitre). The (UV-) transparent sample carrier “SpeChip” incorporates 96 closed sample channels with four measuring chambers each.

Advantages

The four chambers can be raised step by step, which enables measuring with four different thicknesses of layers in one single measurement process. The design according to the 96 and 384 standard format allows the sample carriers to be used with established robotic platforms and spectrophotometers without further adjustment.

Options for companies

A casting process was applied to make the new “SpeChip” sample carriers at the Institute. KIT is now looking for KIT production and distribution partners for further development and industrial manufacture of the microfluidic disposable sample carriers.

Your contact person for this offer

Innovation Manager Energy Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25335

Email: pelisson-schecker@kit.edu