Technology Offers

Search by categories

With biohybrid composite material to 3D cell culture model

KIT has developed a unique process to produce customized three-dimensional composite materials for the coating of culture vessels. The biohybrid materials have precisely controllable mechanical properties.

- Plant engineering

- Automation / IT

- Process and production engineering

- Energy technology

- Electrical engineering

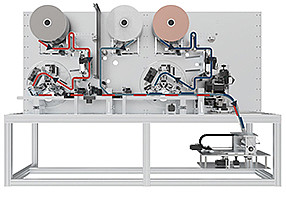

Format-flexible and continuous cell stack assembly

A new plant concept from KIT enables the flexible and continuous production of cell stacks in individual formats. A format change is possible without changing tools.

- Plant engineering

- Electrical engineering

- Mechanical engineering

- Process and production engineering

- Measurement technology

Dry battery electrodes efficiently and modularly

Inline measurement technology and customizable air routing ensure data-based control of drying systems and thus reduce rejects and set-up times.

Thermal validation with dummy battery cell

A battery cell model from KIT enables safe and efficient thermal evaluation of battery systems under real conditions.

- Aerospace industry

- Automotive industry

- Electrical engineering

- Energy and water supply

- Energy technology

- Measurement technology

- Mechanical engineering

- Process and production engineering

- Automation / IT

- Simulation and data processing

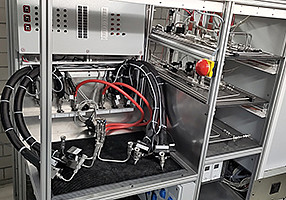

Performance test for fuel cell systems

A new KIT fuel cell test bench simplifies the testing of complete fuel cell systems with interchangeable subcomponents.

- Automotive industry

- Building industry

- Coating technology

- Aerospace industry

- Raw material and textile industry

- Polymer industry

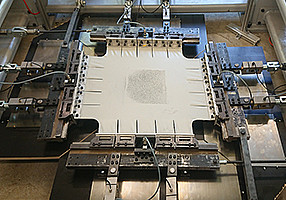

Measuring device for stress states in textiles

Biaxial test facility at KIT measures arbitrary stress and distortion states in flat membrane materials such as textiles and films.

Combined heat and power system for stationary electrical storage

New thermal coupling system for stationary electrical energy storage combines electricity storage with heat supply for buildings.

Direct wind-to-heat conversion via eddy current

KIT has developed a device for the direct conversion of intermittent wind energy into a stable heat source for power generation and industrial applications.

- Electrical engineering

- Process and production engineering

- Microtechnology / precision mechanics

- Chemical industry

- Raw material and textile industry

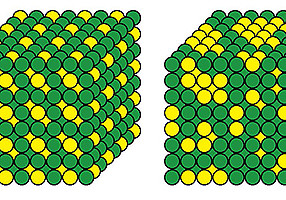

Mechanochemically induced recycling of lithium-ion batteries

With a new recycling process developed by KIT, lithium can be efficiently reclaimed from the cathode material of old batteries without irreversible contamination and environmental damage.

- Coating technology

- Chemical industry

- Polymer industry

- Raw material and textile industry

- Process and production engineering

Intermetals as a catalytically active layer

Intermetallic sputtering targets from KIT improve the reproducible coating of microstructured surfaces using DC magnetron sputtering. The thin catalytic layers make the hydrogenation of acetylene, for example, even more efficient.