Preventing cracks in electrode material

One of factors making a smartphone, tablet PC or laptop attractive is the efficiency and life of the accumulator. Researchers are therefore attempting to improve energy stores so that they will still perform optimally even after several thousand charging and discharging processes.

State of the art

Aspects that efficiency depends on include the processes in the electrode material, which, as a rule, consists of solids with a regular lattice structure. In order for an accumulator to supply electricity, the transition metals in the cathode material have to take up and then emit electrons. To balance the charge, positively charged metal ions, frequently lithium ions, are stored in the electrode material and then released from it again. Each time they are stored, the solid body lattice expands a little, and in the reverse processes, it shrinks together again. These changes in volume in the crystal structure can result in fine cracks in the electrode material. Efficiency therefore gradually decreases, and in the worst case, the accumulator will completely fail.

Technology

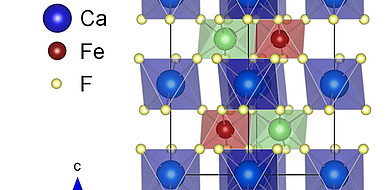

KIT researchers at the Institute for Applied Materials (IAM-KWT) have developed an electrode material that could make accumulators more reliable in the future. It is a lithium-metal fluoride that is suitable as a cathode material and contains both lithium and two further metals, such as iron and calcium. During the charging and discharging processes, the lattice spacing of the electrode material, which has a colquiriite structure, remains almost unchanged, which is characteristic of so-called zero-strain material. In comparison to the currently employed cathode materials, changes in volume are significantly smaller, and the risk of cracks forming is consequently lower.

Advantages

The new cathode material is suitable for the construction of long-life accumulators such as those used in mobile electric devices. In addition, this development offers advantages for apparatus and sensors that are installed at difficult to access locations and that use accumulators which can only be replaced with a considerable effort.

Options for companies

KIT is looking for partners to further develop and apply the technology in practical contexts.

Your contact person for this offer

Innovation Manager Energy Karlsruhe Institute of Technology (KIT)

Innovation and Relations Management (IRM) Phone: +49 721 608-25335

Email: pelisson-schecker@kit.edu